Brand: ZCL

Product Origin: China

Delivery Time: 45-90 days

Supply Capacity: 50 units/month

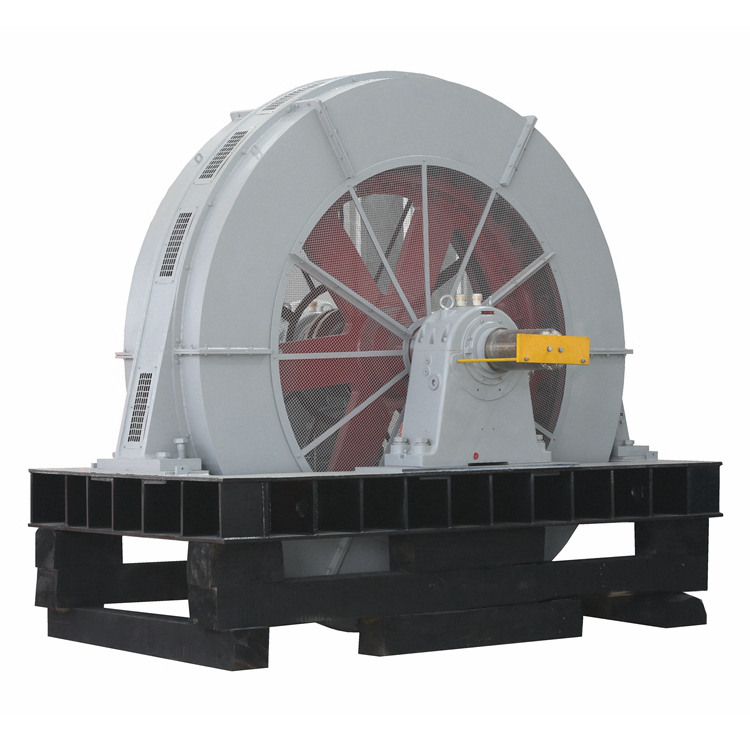

Large high-voltage synchronous motors are ventilated by open natural ventilation or can be made into fully enclosed ducted ventilation.

High-voltage synchronous motor base: welded by steel plate, the lower part of the base is the outlet end of the motor.

The rotor of a large synchronous motor: the magnetic pole is made of steel plate, and is mounted on the rotor yoke together with the magnetic pole coil. The magnetic pole coil is B-class or F-class insulation. When the user uses the pneumatic clutch, the rotary shaft design can be designed according to user requirements or The shaft is punched (the center is long and the through hole is blocked, the shaft end is blocked, the air head is installed on the shaft head, and the other end is processed as required, and the bolt hole is connected to the rotary joint of the air clutch).

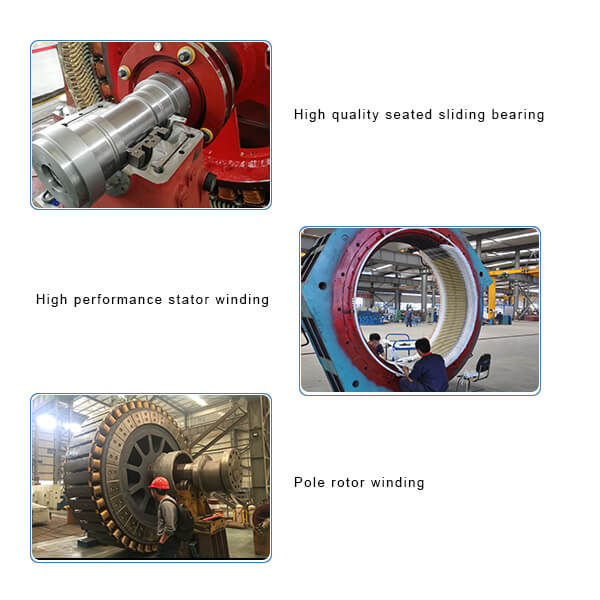

The stator core of the synchronous motor is formed by stacking segments of 0.5 mm thick low-loss silicon steel sheet, and the core segments are separated by radial ducts; the windings are formed by double-stacked short-span coils, using Class B insulation or Class F insulation, temperature rise according to Class B assessment to facilitate extended service life; winding ends are reliably fixed and tied, and vacuum pressure impregnated solventless paint process (VIP) treatment, after multiple turns in the manufacturing process Withstand voltage and ground pressure test, the motor has excellent insulation performance, good mechanical strength and strong moisture resistance.

Our company's large-scale high-voltage synchronous motor is a professional synchronous motor supplier based on years of R&D and production experience and the introduction of advanced manufacturing technology. The technical requirements of this series of motors, except those specified in the special technical conditions of the products, are in compliance with the IEC standards. The mechanical dimensions of each part of the motor are in accordance with the Chinese national standard GB1800-1804 and the ISO standard of the International Standardization Committee.

The protection level of the large synchronous motor housing has IP00, IP20, IP21, IP23 and IP44 according to GB4942.1 and IEC34-5 "Motor enclosure protection level".

This series of synchronous motor cooling methods are based on GB1993 and IEC34-6 "Motor Cooling Method" standards, including IC01, IC27, IC37, IC81W, and IC91W. The basic installation method of the motor complies with the provisions of GB997 and IEC34-7 "Motor Structure and Installation Type Code". If the user needs other protection levels, cooling methods, and installation methods, they can be negotiated separately.

The direction of rotation of the motor is clockwise from the end of the shaft. The motor allows direct starting at full pressure. The motor housing protection type is heavy straight anti-drip type, and can also be other forms. According to user requirements, the ventilation form of the motor can be ventilated or reversed (wind inlet).

Excitation mode: This series of motor excitation system uses thyristor excitation device.

The stator core is formed by laminating silicon steel sheets of 0.5 mm, and the stator core is fixed on the frame by a tensioning screw.

Stator coil: The coil is a stack winding, which is insulated by F pole and has anti-corona measures. The ends of the coils are securely fastened and treated with an integral VPI vacuum dipping finish.

Magnetic pole: a magnetic pole punch punched from a thin steel plate is laminated, and a magnetic pole core jacket is a magnetic pole coil. The entire magnetic pole is mounted on the yoke.

Magnetic pole coil: It is made of copper flat wire and is insulated by Class F insulation.

The front and rear bearings of the large synchronous motor adopt a seat type sliding bearing, and the bearing is equipped with a pressure thermometer and a transparent cover for oil filling. Check holes for easy oil filling and oil mist spillage. The slip ring assembled by the motor is fixed to the non-axial extension end of the main shaft and is coaxial with the main shaft. The jump is small and easy to overhaul. The slip ring brush holder is fixed to the seat block of the non-shaft end. Motor bearings, winding temperature measurement and heating devices can also be added according to customer requirements.

Product Parameters

Product Name: High Voltage Synchronous Motor

Rated voltage: 3000V, 6000V, 10000V, 13800v

Capacity range: 400 kW ~ 6000kW

Rated frequency: 50Hz, 60HZ

Cooling method: IC01, IC27, IC37, IC81W,

Working system: S1

Synchronous speed: 150-1500r/min

Insulation class: Class F

Temperature rise level: B

Connection: Y

Protection level: IP00/IP21/IP23

Power factor: 0.9 (leading)

Excitation mode: static thyristor (other excitation methods can also be made)

The guaranteed value of the ratio of out-of-step torque to rated torque at rated voltage is 1.7

The guaranteed value of the ratio of locked rotor torque to rated torque at rated voltage is 1.0.

The guaranteed value of the ratio of the torque to the rated torque at the rated voltage is 0.7.

The guaranteed value of the ratio of locked current to rated current at rated voltage is 7.0.

Mine synchronous motor use altitude: no more than 1000m, the allowable voltage deviation range is ± 5%, because the power factor is ahead, the grid has a certain compensation effect. This type of motor is suitable for use in environments where the ambient air temperature does not exceed 40 ° C and there is no serious dust, the minimum ambient air temperature is -15 ° C, and there is no corrosive and explosive gas in the air (which can also be made into a damp heat or high-altitude motor).

Feature of Product

High-voltage synchronous motors have large moment of inertia characteristics and are widely used in petroleum. Chemical, electric power and other industries are used to drive loads with large moments of inertia such as fans, pumps and compressors. This series of motors adopts new technology, new materials, new technology, colorful and exquisite, well-made, specific small size, light weight, high efficiency, low noise, low vibration, safe and reliable operation, convenient use and maintenance.

Packing and Shipping

1. The outer packaging of the products are all standard export-oriented wooden plywood packaging.

2. The product packaging is protected by moisture, water plastic soft packaging

3. For products with special transportation requirements (such as temperature, fragile, variability, and easy to get wet), the packaging protection measures will be strengthened, and the target mark will be printed on the package.

4. There are obvious signs and symbols on the packing box that must be paid attention to during transportation and storage (such as position, moisture, rain, shockproof, lifting position, etc.).

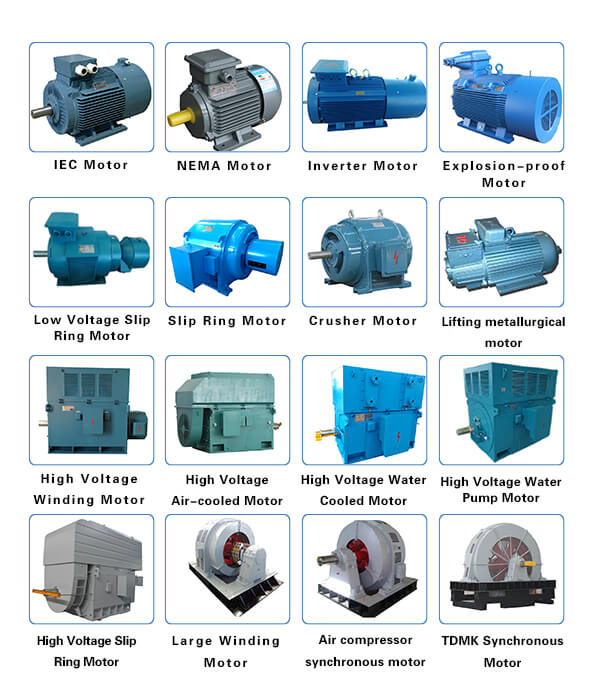

More Product

There are many types of motor products manufactured and sold by our company. The main products are high- and low-voltage three-phase asynchronous motors. The motor structure types include squirrel-cage type and winding type. Among them, high-voltage synchronous motors mainly support air compressors and mine ball mill equipment. use. We adhere to the service tenet of "focus on products, service with heart" and provide high-quality motor products to customers.

Factory Glimpse

Our company's motor manufacturing factory adheres to the concept of green, efficient and energy-saving production service, pays attention to the harmonious development of internal and external environment, builds environmentally friendly motor manufacturing enterprises, strictly implements motor standard process, and selects high-quality energy-saving materials to ensure the quality of motor products.

About Us

Shijiazhuang ZCL Electric Motor Technology Co., Ltd. is a company mainly engaged in the manufacture, research and development and sales of motor products. The company has many types of motor products, including IEC standard motors. It is a professional IEC motor manufacturer. Related motor products have passed the product certification in China, the United States, Canada, Europe, the Middle East and other regions, and the products are exported to all over the world. Companies adhere to the "focus on products, service" business philosophy, is committed to improving the quality of safe motor products and services for customers around the world.

FAQ

More details, welcome to call us!

Q: What are the payment terms?

A: 30% T/T in advance, 70% before shipment

Q: What is your delivery time?

A: Different models with different time, 10-90 days after order confirmed.

Q: What is your MOQ?

A: It depends on model.

Q: Where is your loading port?

A: Shanghai or Tianjing Port, China.

Synchronous Motors for Air Separation Applications

TK series three-phase synchronous motor is a high-voltage synchronous motor specially designed for air compressors, mainly used in refrigeration and fertilizer industry equipment.

Synchronous Motors for Air Separation Applications

TK series three-phase synchronous motor is a high-voltage synchronous motor specially designed for air compressors, mainly used in refrigeration and fertilizer industry equipment.

Synchronous Motors for Mining Applications

Large-scale synchronous motor ventilation for mines is open-type natural ventilation or can be made into fully enclosed pipeline ventilation.

Synchronous Motors for Mining Applications

Large-scale synchronous motor ventilation for mines is open-type natural ventilation or can be made into fully enclosed pipeline ventilation.

Large Synchronous Excitation Electric Motor

The large synchronous motor is a horizontal three-phase salient-pole synchronous motor. The installation method of the motor is horizontal installation. The outer casing of the motor has a circular structure, the protection grade is IP20, and the cooling mode is open ventilation cooling.

Large Synchronous Excitation Electric Motor

The large synchronous motor is a horizontal three-phase salient-pole synchronous motor. The installation method of the motor is horizontal installation. The outer casing of the motor has a circular structure, the protection grade is IP20, and the cooling mode is open ventilation cooling.

Synchronous 8 to 40 Poles Motors

The 8 to 40 pole synchronous motor is a horizontal three-phase salient-pole synchronous motor.

Synchronous 8 to 40 Poles Motors

The 8 to 40 pole synchronous motor is a horizontal three-phase salient-pole synchronous motor.

TDMK large synchronous slip ring motor for ball mill

This series of ball mill synchronous motor is mainly suitable for large AC three-phase synchronous motor used in transmission mine mill. The main transmission lattice ball mill, rod mill, coal mill mining equipment.

TDMK large synchronous slip ring motor for ball mill

This series of ball mill synchronous motor is mainly suitable for large AC three-phase synchronous motor used in transmission mine mill. The main transmission lattice ball mill, rod mill, coal mill mining equipment.

187.5RPM 400KW Synchronous Motor

Our 400KW synchronous motor is a high-power AC motor that operates at a constant speed synchronized with the supply frequency. It converts electrical energy into mechanical energy efficiently and is widely used in heavy-duty industrial applications where precise speed control and high torque are essential.

187.5RPM 400KW Synchronous Motor

Our 400KW synchronous motor is a high-power AC motor that operates at a constant speed synchronized with the supply frequency. It converts electrical energy into mechanical energy efficiently and is widely used in heavy-duty industrial applications where precise speed control and high torque are essential.

40p 1600KW High Voltage Permanent Magnet Synchronous Motor

The drive mode of 40p-1600KW high-voltage permanent magnet synchronous motor adopts the pinion of permanent magnet motor directly driven ball mill, which can greatly improve work efficiency and running cost.

40p 1600KW High Voltage Permanent Magnet Synchronous Motor

The drive mode of 40p-1600KW high-voltage permanent magnet synchronous motor adopts the pinion of permanent magnet motor directly driven ball mill, which can greatly improve work efficiency and running cost.

Synchronous Motor Supplier

Large high-voltage synchronous motors are ventilated by open natural ventilation or can be made into fully enclosed ducted ventilation.

Synchronous Motor Supplier

Large high-voltage synchronous motors are ventilated by open natural ventilation or can be made into fully enclosed ducted ventilation.

Synchronous 4 and 6 Poles Motors

The T Series 4 and 6 pole high speed synchronous motors are horizontal.

Synchronous 4 and 6 Poles Motors

The T Series 4 and 6 pole high speed synchronous motors are horizontal.

Copyright © ZCL Electric Motor Technology Co., Ltd. All Rights Reserved | Sitemap | Powered by