Brand: ZCL

Product Origin: China

Delivery Time: 30-60 days

Supply Capacity: 300 units/month

If you want to know more about Slip Ring Induction Motor Price, just contact us.

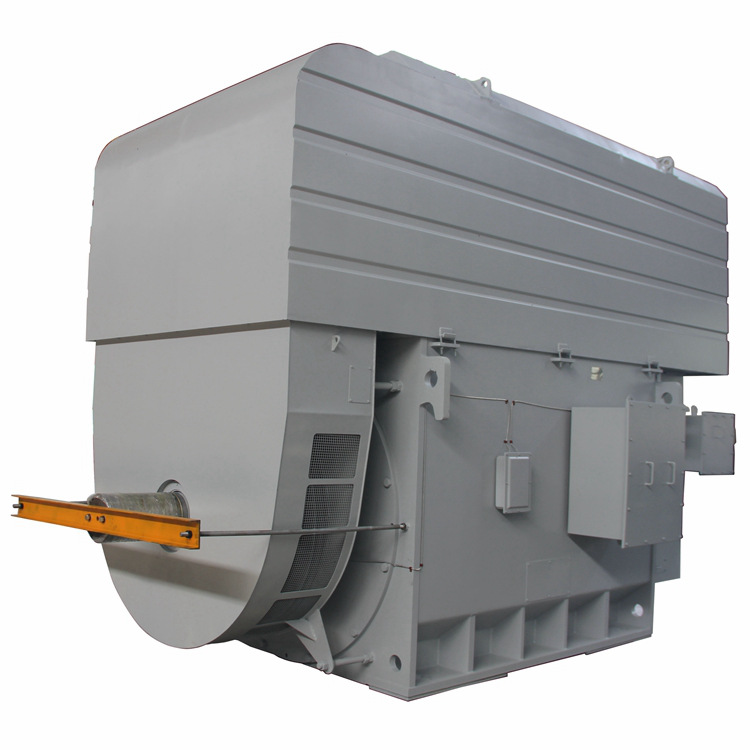

The Slip Ring Induction Motor from ZCL is a highly efficient and versatile electrical device that converts electrical energy into mechanical energy. Its design ensures self-starting capabilities, making it ideal for industrial applications requiring high torque. This motor, a type of AC Slip Ring Motor, offers numerous advantages, including low starting current, high starting torque, and improved power factor. Our Slip Ring Induction Motor is a wound rotor, 3-phase asynchronous motor designed for demanding applications. The YR series (IP44) model is an updated version that complies with IEC and DIN42679 standards, ensuring global compatibility in power levels and installation sizes.

Frame number range: 280-315

Power range: 55-220KW

Voltage: 380V/415V/440V/660V/690V/1140V

Number of poles: 4/6/8/10/12

Rated frequency: 50Hz/60Hz

Protection level: IP44 (slip ring protection class IP23)

Cooling method: IC411

Working system: S1

Insulation class: Class F

Wiring method: stator △ connection method, the rotor is the Y connection method

Installation method: B3 (horizontal installation)

Ambient temperature: ≥ -15 ℃ and ≤ 40 ℃

The YR series Slip Ring Induction Motor from ZCL is built for reliability, featuring IP44 protection that allows it to operate in dusty environments and areas with slightly corrosive or humid conditions.

This motor offers a high starting torque with low initial current, making it suitable for applications requiring precise control and speed adjustment, such as cranes, elevators, and compressors.

The motor's structural components, including the stator and rotor, are designed to be interchangeable with other Y-series motors, offering convenience and flexibility for users.

1. The outer packaging of the slip ring motors is all standard export-oriented wooden plywood packaging.

2, the slip ring motor packaging is protected from moisture, water plastic soft packaging

3. For slip ring motors with special transportation requirements (such as temperature, fragility, variability, and easy of getting wet), the packaging protection measures will be strengthened, and the target mark will be printed on the package.

4. There are obvious signs and symbols on the packing box that must be paid attention to during transportation and storage (such as position, moisture, rain, shockproof, lifting position, etc.).

This motor is widely used in scenarios where:

High starting torque is needed (e.g., compressors, sugar mills).

The feeder line capacity is insufficient for squirrel cage motors.

A small range of speed regulation is required.

Mechanical equipment operates under special working conditions.

Industries and machines benefiting from this motor include:

Ball mills, fans, compressors, and water pumps.

Large torque inertia fans, rolling mills, and electric shovels.

Conveyor systems and winches.

The ZCL's YR series Slip Ring Induction Motor complies with ISO9001, CCC/COC, CE, UL, and other international certifications. These standards guarantee superior quality and energy efficiency.

Shijiazhuang ZCL Electric Motor Technology Co., Ltd. specializes in motor manufacturing and R&D. With IEC-compliant products exported worldwide, we focus on delivering safe, high-quality motor solutions tailored to customer needs.

Slip is defined as the difference between synchronous speed and operating speed, at the same frequency.

They are used in centrifugal pumps, large blowers, and fans, to run conveyor belts, etc.

A motor with a wound-type rotor is known as a slip-ring induction motor. Also, rotor windings are connected through slip rings to external resistance.

The disadvantages are high copper losses and the low torque

The external resistance acts as a variable rheostat during the motor kick-off and tweaks automatically to high resistance to get the required starting current.

The difference between these two motors is discussed below.

| Slip Ring Motor | Squirrel Cage Motor |

| It has a rotor of wound-type | Its rotor is of squirrel cage type |

| The rotor has cylindrical core has parallel slots, in which each slot has a bar | Slots are not parallel to each other |

| Construction is complicated because of slip rings and brushes | Construction is simple |

| The external resistance circuit is connected to a motor | No external resistance circuit as the bars of the rotor are completely slotted |

| The starting torque is high | Torque is low |

| Efficiency is low | Efficiency is high |

The advantages are

High and excellent starting torque to support high inertia loads.

It has a low starting current due to external resistance

Can take full load current that is 6 to 7 times higher

The disadvantages are

Includes higher maintenance costs due to brushes and slip rings compared to squirrel cage motor

Intricate construction

High copper loss

Low efficiency and low power factor

Expensive than 3 3-phase squirrel cage induction motor

Slip is defined as the difference between the flux speed and the rotor speed. For an induction motor to produce torque, at least some difference should be there between stator field speed and rotor speed. This difference is called ‘slip’. The Slip Ring” is an electromechanical device that aids in transmitting power and electrical signals from a stationary to a rotating component.

Slip rings are also known as rotary electrical interfaces, electric rotary joints, swivels, or collector rings. Sometimes, based on the application, the slip ring requires a higher bandwidth to transmit data. Slip rings improve the efficiency and performance of a motor by improving system operation and eliminating wires that are dangling from motor joints.

There are many types of motor products manufactured and sold by our company. The main products are high- and low-voltage three-phase asynchronous motors. The motor structure types include the squirrel-cage type and winding type. Among them, high-voltage synchronous motors mainly support air compressors and mine ball mill equipment. use. We adhere to the service tenet of "focus on products, service with heart" and provide high-quality motor products to customers. Click here to view more induction motors.

If you want to know more about Slip Ring Induction Motor Prices, please fill out the form below carefully and we will have a professional team contact you.

415V Slip Ring Motor

YZR series motors are hoisting metallurgy special winding slip ring AC motors.

415V Slip Ring Motor

YZR series motors are hoisting metallurgy special winding slip ring AC motors.

Hot Selling Slip Ring Motor

The YR3 series (IP54) slip ring motor is a closed-wound rotor three-phase asynchronous motor, which is a new generation of design.

Hot Selling Slip Ring Motor

The YR3 series (IP54) slip ring motor is a closed-wound rotor three-phase asynchronous motor, which is a new generation of design.

High Quality Slip Ring Motor

The high-quality slip ring motor adopts box-type structure.

High Quality Slip Ring Motor

The high-quality slip ring motor adopts box-type structure.

High Voltage Slip Ring Induction Motor

YRKK series HV slip ring induction motors are used in the motors of heavy-duty starting equipment such as ball mills, rolling mills, sugar mills, crushers, etc.

High Voltage Slip Ring Induction Motor

YRKK series HV slip ring induction motors are used in the motors of heavy-duty starting equipment such as ball mills, rolling mills, sugar mills, crushers, etc.

Copyright © ZCL Shijiazhuang Electric Motor Technology Co.,Ltd.(中磁力石家庄电机科技有限公司)All Rights Reserved | Sitemap | Powered by