Brand: ZCL

Product Origin: China

Delivery Time: 30-60 days

Supply Capacity: 500 units/month

YZR series motors are hoisting metallurgy special winding slip ring AC motors. This type of motor has high overload capacity and mechanical strength. It is suitable for short-term or intermittent periodic working system, frequent starting, braking, and significant Vibration and impact equipment used.

YZR 415V slip ring motor power class and installation dimensions are in line with IEC recommendations. The interchange of power class and installation size is similar to JEM1202 in Japan and DIN42681 in Germany, most of which are interchangeable.

The YZR winding slip ring motor has a good seal. The motor protection class for general locations is IP44 and the motor protection rating for metallurgical sites is IP54.

YZR series lifting metallurgy winding slip ring AC motor, suitable for motor lifting of large equipment. This model of motor installation size and power level are in line with IEC standards. The motor has high overload capacity and mechanical strength, and is especially suitable for short-term or intermittent operation, frequent starting, braking and equipment with significant vibration and impact.

The insulation grade of the motor is divided into two grades, F and H. Class F is suitable for general locations where the temperature of the cooling medium does not exceed 40 ° C; Class H is suitable for metallurgical sites where the temperature of the cooling medium does not exceed 60 ° C. Both motors have the same parameters. The metallurgical motor housing is rated IP54; the lifting motor housing is IP44. The metallurgical motor has an insulation rating of Class H and a lifting motor with Class F insulation. The motor stator junction box is located on the top of the base and can be wired from either side of the base. The motor is driven by a coupling or a gear. When the spur gear is used, the pitch diameter of the gear should be not less than twice the diameter of the shaft. Motor cooling method is IC0041 for frame number 112-132, IC0141 for frame number 160-355, and IC0151 for frame number 400.

Product Parameters

Frame number: 112-400

Power range: 1.8KW-270KW

Voltage: 380V/415V/440V/660V/690V

Protection level: IP44/IP54

Frequency: 50HZ/60HZ

Cooling method: IC0041/IC0141/IC0151

Working system: S2/S3/S4/S5

Insulation class: F, H class

The motor can operate normally under the following conditions

(1) Indoor dusty places

(2) Class F insulation is used in general environment, the ambient air temperature is not more than +40 °C, Class H insulation is used in metallurgical environment, and the ambient air temperature is not more than +60 °C.

(3) The altitude does not exceed 1000m

(4) Equipment with significant vibration and shock

(5) frequent starting, braking and reversing

Feature of Product

YZR winding slip ring motor is suitable for lifting metallurgical related mechanical equipment. The motor has high overload capacity and mechanical strength. It is suitable for short-term or intermittent periodic working system, frequent starting, braking, and significant vibration. With impact equipment.

This type of motor casing has a high strength cast iron casing, the motor junction box is located at the top of the motor, the motor fan is a good performance cast aluminum fan, and the motor slip ring uses a high quality copper slip ring.

Equipment Capacity

The company has large-scale laboratory, intelligent CNC winding machine, CNC rising machine, automatic wrapping machine, VPI high pressure vacuum immersion system, large-scale dipping paint drying furnace, 60 tons test platform, large vertical car, milling machine, grinding machine, Each type of dynamic balancing machine, double-feedback test and detection system with 6MW (12MW) motor and other motor production professional equipment more than 500 sets, sound mechanical equipment processing capacity, to lay a good foundation for customers to improve good quality motor products.

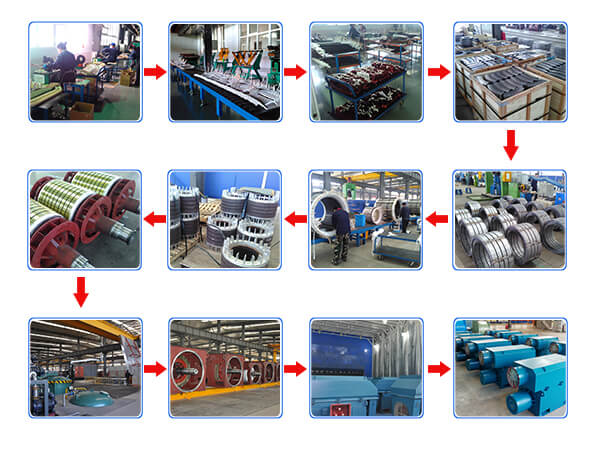

Main Process Flow of the Motor

Motor stator: casing processing → punching press → iron core seating → coil making → weaving → dipping paint drying

Electronic rotor: blank shaft processing → iron core press installation → iron core cast aluminum → rotor string shaft → weave → dipping paint drying → dynamic balance

Motor assembly: stator rotor assembly → machine test → motor appearance coloring → packaging storage

About Us

Shijiazhuang ZCL Electric Motor Technology Co., Ltd. is a company mainly engaged in the manufacture, research and development and sales of motor products. The company has many types of motor products, including IEC standard motors. It is a professional IEC motor manufacturer. Related motor products have passed the product certification in China, the United States, Canada, Europe, the Middle East and other regions, and the products are exported to all over the world. Companies adhere to the "focus on products, service" business philosophy, is committed to improving the quality of safe motor products and services for customers around the world.

Contact Us

If you are interested in our products motor, please feel free to contact us! Thank you very much!

Shijiazhuang ZCL Electric Motor Technology Co., Ltd.

Add.: Industrial Zone, Zhangjiazhuang Town, Airport Road, Gaocheng District, Shijiazhuang, Hebei, China

TEL./Fax: +86 139 3119 2007/ +86 311 8924 6924

SKYPE:+86 139 3119 2007

QQ: 568151260

Welcome to visit our factory!

E-mail: zclgroup@zcl-group.com

Hot Selling Slip Ring Motor

The YR3 series (IP54) slip ring motor is a closed-wound rotor three-phase asynchronous motor, which is a new generation of design.

Hot Selling Slip Ring Motor

The YR3 series (IP54) slip ring motor is a closed-wound rotor three-phase asynchronous motor, which is a new generation of design.

Wound Rotor Slip Ring Motor

A Wound Rotor Motor, also known as a Slip Ring Motor, is an electric motor with a unique rotor design that sets it apart from other types of motors. Unlike standard motors with permanent magnets or squirrel-cage rotors, the wound rotor motor features a rotor with windings that have electrical connections to external slip rings.

Wound Rotor Slip Ring Motor

A Wound Rotor Motor, also known as a Slip Ring Motor, is an electric motor with a unique rotor design that sets it apart from other types of motors. Unlike standard motors with permanent magnets or squirrel-cage rotors, the wound rotor motor features a rotor with windings that have electrical connections to external slip rings.

AC Slip Ring Motor

YR series AC slip ring (IP23) motor is a protective wound rotor asynchronous motor.

AC Slip Ring Motor

YR series AC slip ring (IP23) motor is a protective wound rotor asynchronous motor.

YR Series (IP44) Slip Ring Induction Motor

YR series (IP44) slip ring induction motor is a general-purpose wound rotor three-phase asynchronous motor. It is the latest design and updated product.

YR Series (IP44) Slip Ring Induction Motor

YR series (IP44) slip ring induction motor is a general-purpose wound rotor three-phase asynchronous motor. It is the latest design and updated product.

Slip Ring Motor for Ball Mill

YRQ winding slip ring motor is specially designed for ball mill. This series of motors is a derivative of the original JR slip ring motor.

Slip Ring Motor for Ball Mill

YRQ winding slip ring motor is specially designed for ball mill. This series of motors is a derivative of the original JR slip ring motor.

Copyright © ZCL Shijiazhuang Electric Motor Technology Co.,Ltd.(中磁力石家庄电机科技有限公司)All Rights Reserved | Sitemap | Powered by