Brand: ZCL

Product Origin: China

Delivery Time: 25-50 days

Supply Capacity: 300 units/month

The stator structure of IE4 low-voltage super-efficient permanent magnet synchronous motor is similar to that of ordinary Y series asynchronous motor. The company's R&D team uses modern high-performance motor design theory and design technology to optimize the core and winding; the rotor is placed in the high-performance rare earth “Magnetic King”, which optimizes the squirrel cage structure and can produce higher than ordinary asynchronous motors at rated voltage and rated frequency. Starting torque.

The rare earth "Magnetic King" is recognized as the world's most permanent magnet material with the highest magnetic energy content, saturated magnetization, and presents a "permanent magnetic field". After the High Efficiency Permanent Magnet Motor is installed, no reactive current excitation current, permanent magnetic field of "Magnetic King", interaction with the three-phase current of the winding, and stable electromagnetic torque are generated to drive the load.

This structural feature of the IE4 ultra-efficient permanent magnet synchronous motor makes the power factor high. Under the condition of ensuring the same output power, the current is significantly reduced, the resistance loss of the winding is reduced, and there is substantially no rotor loss during operation, which exhibits remarkable high efficiency and energy saving characteristics. Due to the reduction of the total loss, the temperature rise is reduced by more than 30K compared with the conventional asynchronous motor, and the operating life is prolonged. This is the basic working principle of a permanent magnet synchronous motor.

The basic series of IE4 ultra-efficient permanent magnet synchronous motor is three-phase, 380V, fully enclosed fan air cooling, protection class IP54, class F insulation, installation form IMB3, working system S1. It can meet the requirements of users for other voltage levels 690V, 1140V, protection level, cooling method, installation form, etc. Our company is committed to providing customers with a total solution for the motor drive system. When the customer needs more than 1500 rpm (less than 500 rpm), the inverter is used for power supply.

IE4 high-efficiency permanent magnet motor products are developed and manufactured according to China JB/T 13297-2017 "TYE4 series three-phase permanent magnet synchronous motor technical conditions" standard, and the efficiency is in line with China GB30253-2013 "Permanent Magnet Synchronous Motor Energy Efficiency Limit Value and Energy Efficiency Rating" The first-class standard has reached the international advanced level of similar products and is listed in the first batch of high-efficiency and energy-saving motor promotion catalogues of the China Development and Reform Commission.

IE4 high-efficiency permanent magnet motor product range 132-355, power level and installation size fully comply with the International Electrotechnical Commission (IEC) standards, product efficiency in line with GB30253-2013 "permanent magnet synchronous motor energy efficiency limit value and energy efficiency rating" 1 Level standards, reaching the international advanced level of similar products.

IE4 high efficiency permanent magnet motor products are fully enclosed, self-fan cooling structure. The utility model has the advantages of novel design, compact structure, beautiful appearance, high efficiency and torque, good starting torque performance, energy saving, low noise, small vibration, safe and reliable operation and the like. This series of motors are widely used in industrial and mining enterprises such as petrochemical, electric power, transportation, textile, etc., and are used to drive various machines such as fans, pumps, compressors, belt conveyors and machine tools.

The product uses the "no difference replacement" design technology with the IE2 series motor. Corresponding to the IE2 series motor voltage level and installation size, it can achieve “no difference” replacement; at rated voltage and rated frequency, it has self-starting capability, synchronous operation and no slip.

IE4 ultra-efficient permanent magnet synchronous motor has the advantages of novel design, compact structure, beautiful appearance, high efficiency and torque, good starting torque performance, energy saving, low noise, small vibration and safe and reliable operation. This series of motors are widely used in industrial and mining enterprises such as petrochemical, electric power, transportation, textile, etc., and are used to drive various machines such as fans, pumps, compressors, belt conveyors and machine tools.

The motor adopts Class F insulation. The machine seat No. H180 has a fuel injection and discharge device. If the user requires the stator to measure temperature, the working mode is S1, the cooling mode is IC411, the protection degree of the casing is IP54, and the "W" outdoor can be produced at the same time. , "TH" wet tropical, "WTH" outdoor wet tropical, "W (F1 - F2)" anti-corrosion type (F1 is medium anti-corrosion, F2 is strong anti-corrosion), the heat sink of the motor is vertical and horizontal distribution, motor wiring The position of the box (according to the frame number) is divided into two structures (see installation and external dimensions) for the side and top of the frame (for installation and dimension drawing), the user can choose to use it (the terminal box is on the right side when not specified).

Base range: 80-355

Power range: 0.75kW-315kW

Frequency: 50/60Hz

Number of levels: 2/4/6/8/10/12

Energy efficiency rating: IE4

Working system: S1

Protection level: IP54/IP55

Insulation class: F

Cooling method: IC411

Applications: Drag fans, pumps, compressors, belt conveyors, machine tools and other machinery.

IE4 ultra-efficient permanent magnet motor has self-starting capability. It has higher efficiency than the asynchronous motor of the same specification in the range of 25%---120% load, and has wide economic operation range and remarkable energy saving effect. The temperature rise of the motor is low. Under the rated load, the temperature rise of the motor is 30-50K.

In addition to excellent high-efficiency, energy-saving and economical operation and high power factor characteristics, IE4 low-voltage ultra-high-efficiency permanent magnet synchronous motor has the following advantages in motor running and under load conditions:

1. The operating current is significantly reduced

2. The temperature rise is reduced by more than 30K, and the operating life is prolonged.

3. Reduce the distribution network current and reduce the cable temperature rise

4. Reduce the reactive power compensation capacity of enterprise distribution network

5. Starting torque multiple is higher than the same power asynchronous motor, lifting heavy load starting performance

Product use conditions: altitude below 1000 meters, ambient temperature -15 ° C ~ +40 ° C.

The motor products manufactured and sold by our company are used in many industries, such as electric power, mining, steel metallurgy, petrochemical, water conservancy, transportation, building materials and many other industries. The equipment for the motor is pump, machine tool, fan, mill, crusher, rolling mill, compressor and many other industrial equipment.

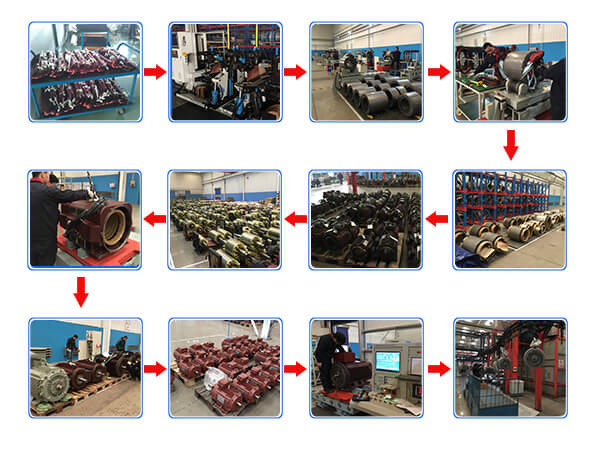

Motor stator: casing processing → punching press → iron core seating → coil making → weaving → dipping paint drying

Electronic rotor: blank shaft processing → iron core press installation → iron core cast aluminum → rotor string shaft → weave → dipping paint drying → dynamic balance

Motor assembly: stator rotor assembly → machine test → motor appearance coloring → packaging storage

Shijiazhuang ZCL Electric Motor Technology Co., Ltd. is a company mainly engaged in the manufacture, research and development and sales of motor products. The company has many types of motor products, including IEC standard motors. It is a professional IEC motor manufacturer. Related motor products have passed the product certification in China, the United States, Canada, Europe, the Middle East and other regions, and the products are exported to all over the world. Companies adhere to the "focus on products, service" business philosophy, is committed to improving the quality of safe motor products and services for customers around the world.

Permanent Magnet Synchronous Motor

A Permanent Magnet Synchronous Motor (PMSM) is a type of electric motor that uses permanent magnets to create a magnetic field within the motor, rather than relying on electromagnets. This design offers several advantages, including higher efficiency, better power density, and smoother operation.

Permanent Magnet Synchronous Motor

A Permanent Magnet Synchronous Motor (PMSM) is a type of electric motor that uses permanent magnets to create a magnetic field within the motor, rather than relying on electromagnets. This design offers several advantages, including higher efficiency, better power density, and smoother operation.

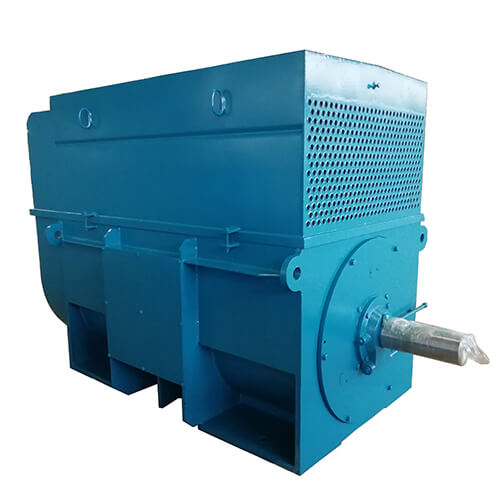

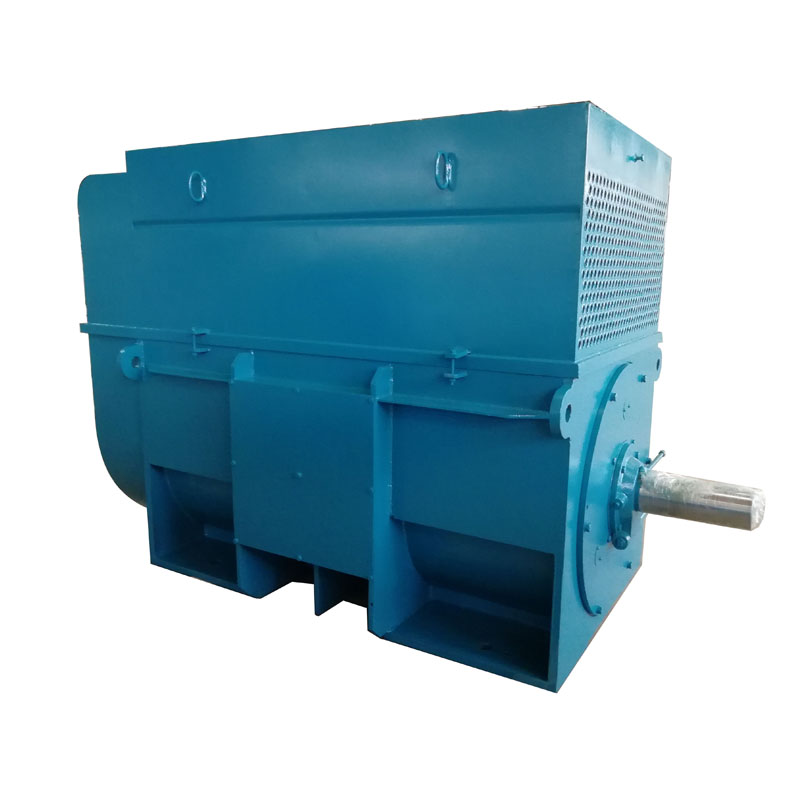

Large Permanent Magnet Synchronous Motor

The stator structure of the high-voltage and high-efficiency asynchronous start large permanent magnet synchronous motor is similar to that of the ordinary Y series high-voltage asynchronous motor.

Large Permanent Magnet Synchronous Motor

The stator structure of the high-voltage and high-efficiency asynchronous start large permanent magnet synchronous motor is similar to that of the ordinary Y series high-voltage asynchronous motor.

IE4 Low Voltage Ultra High Efficiency Permanent Magnet Synchronous Frequency Conversion Motor

The High Efficiency Permanent Magnet Motor is three-phase, 380V, fully enclosed fan air cooling, protection class IP54, class F insulation, installation form IMB3, working system S1.

IE4 Low Voltage Ultra High Efficiency Permanent Magnet Synchronous Frequency Conversion Motor

The High Efficiency Permanent Magnet Motor is three-phase, 380V, fully enclosed fan air cooling, protection class IP54, class F insulation, installation form IMB3, working system S1.

High-voltage High-Efficiency Permanent Magnet Variable Frequency Synchronous Motor

The stator structure of the high-voltage and high-efficiency asynchronous start permanent magnet synchronous motor is similar to that of the ordinary Y series asynchronous motor.

High-voltage High-Efficiency Permanent Magnet Variable Frequency Synchronous Motor

The stator structure of the high-voltage and high-efficiency asynchronous start permanent magnet synchronous motor is similar to that of the ordinary Y series asynchronous motor.

Copyright © ZCL Electric Motor Technology Co., Ltd. All Rights Reserved | Sitemap | Powered by