The permanent magnet synchronous motor product is developed and manufactured according to China JB/T 13297-2017 "TYE4 series three-phase permanent magnet synchronous motor technical conditions", and the efficiency meets the energy efficiency standard of GB30253-2013 "Permanent magnet synchronous motor energy efficiency limit value and energy efficiency grade". To achieve the international advanced level of similar products, listed in the first batch of high-efficiency and energy-saving motor promotion catalog of China National Development and Reform Commission.

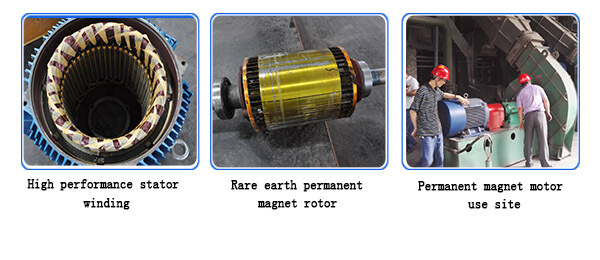

The stator structure of the low voltage high efficiency permanent magnet synchronous motor is similar to that of the ordinary Y series asynchronous motor. Using modern high-performance motor design theory and design technology, the core and winding are optimized; the rotor is placed in the high-performance rare earth “magnetic king”, which optimizes the squirrel cage structure and can generate a higher starting speed than an ordinary asynchronous motor at rated voltage and rated frequency. Moment.

Rare earth "Magnetic King" is recognized as the world's highest permanent magnet material with magnetic energy content, saturated magnetization, and presents a "permanent magnetic field". After the motor is installed, the reactive current is not required, and the permanent magnetic field of the "Magnetic King" interacts with the three-phase current of the winding to generate a stable electromagnetic torque to drive the load.

This structural feature of the permanent magnet synchronous motor makes the power factor high. Under the condition of ensuring the same output power, the current is significantly reduced, the resistance loss of the winding is reduced, and there is substantially no rotor loss during operation, which exhibits remarkable high efficiency and energy-saving characteristics. Due to the reduction of the total loss, the temperature rise is reduced by more than 30K compared with the conventional asynchronous motor, and the operating life is prolonged.

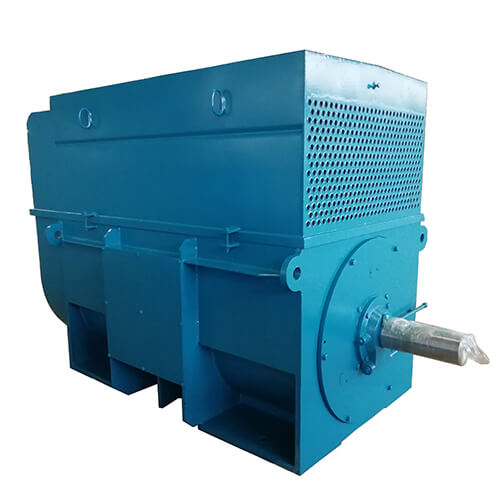

The permanent magnet synchronous motor product series is a three-phase fully enclosed self-fan air-cooled motor. The protection grade of the motor is IP54, the installation form is IMB3, and the working system is S1. It can meet the user's requirements for other voltage levels (415V/690V/1140V), protection level, cooling method, installation form, etc. When the motor speed is higher than 1500 rpm (less than 500 rpm), the inverter is used for power supply.

The universal permanent magnet synchronous motor adopts the "no difference replacement" design technology with the IE2 and IE3 series motors. Corresponding to the voltage level of IE2/IE3 series motor, corresponding to the installation size, it can realize “no difference” replacement; at rated voltage and rated frequency, it has self-starting capability, synchronous operation and no slip.

The high efficiency permanent magnet synchronous motor uses Class F insulation. There is an oil draining device above the frame number H180. If the user requires the stator to measure temperature, the working mode is S1, which is a fully enclosed, self-fan cooling structure. Cooling method is IC411, the enclosure protection grade is IP54, and can produce "W" outdoor, "TH" wet tropical, "WTH" outdoor wet tropical, "W (F1 - F2)" anti-corrosion type (F1 is medium anti-corrosion, F2 For strong anti-corrosion), the explosion-proof type, the heat sink of the motor is vertically and horizontally distributed, and the position of the motor junction box (by the frame number) is divided into two structures (see installation and dimension drawing) for the user to choose. Use (the junction box is on the right side when not specified by the user).

The rare earth permanent magnet synchronous motor has the advantages of novel design, compact structure, beautiful appearance, high efficiency and torque, good starting torque performance, energy saving, low noise, small vibration and safe and reliable operation. This series of motors are widely used in industrial and mining enterprises such as petrochemical, electric power, transportation, textile, etc., and are used to drive various machines such as fans, pumps, compressors, belt conveyors and machine tools.

More details, welcome to call us!

Permanent Magnet Synchronous Motor Parameters

Center height range: H80 ~ 355mm

Power range: 0.75kW to 315kW

Synchronous speed: 3000/1500/1000/750/600 r/min

Number of poles: 2/4/6/8/10/12

Rated voltage: 380V/415V/440V/690V/1140V

Rated frequency: 50HZ/60HZ

Protection level: IP54 or IP55

Power factor: 0.96

Efficiency range: 83.5%-96.8%

Energy efficiency rating: IE4

Insulation class: F

Work system: S1 (continuous)

Cooling method: IC411

Installation form: IMB3

Motor connection: Y (three outlet terminals in the junction box, the junction box from the extension of the spindle is located on the right side of the base)

Altitude: no more than 1000m

This type of motor is suitable for use in environments where the ambient air temperature does not exceed 40 ° C and there is no serious dust, the minimum ambient air temperature is -15 ° C, and there is no corrosive and explosive gas in the air (which can also be made into a damp heat or high-altitude motor).

Feature of Permanent Magnet Synchronous Motor

High efficiency, high power factor;

In addition to excellent high-efficiency, energy-saving and economical operation characteristics, the high-efficiency permanent magnet synchronous motor has the following characteristics under high load factor when the motor is running and under the same load conditions:

1. The operating current is significantly reduced

2. The temperature rise is reduced by more than 30K, and the operating life is prolonged.

3. Reduce the distribution network current and reduce the cable temperature rise

4. Reduce the reactive power compensation capacity of enterprise distribution network

5. The starting torque multiple is higher than the same power asynchronous motor, lifting heavy load starting performance

Product use conditions: altitude below 1000 meters, ambient temperature -15 ° C ~ +40 ° C.

More Product

There are many types of motor products manufactured and sold by our company. The main products are high- and low-voltage three-phase asynchronous motors. The motor structure types include squirrel-cage type and winding type. Among them, high-voltage synchronous motors mainly support air compressors and mine ball mill equipment. use. We adhere to the service tenet of "focus on products, service with heart" and provide high-quality motor products to customers.

Certifications

The motor products manufactured by our company have obtained the ISO9001 quality management management system certification, passed the CCC/COC, China energy-saving product certification, and passed the certification certificates of CE/UL/IRIS/CAS and other European and American countries. The company strictly improves the quality and efficient motor products and services for users in strict accordance with the requirements of relevant product standards.

Factory Glimpse

Our company's motor manufacturing factory adheres to the concept of green, efficient and energy-saving production service, pays attention to the harmonious development of internal and external environment, builds environmentally friendly motor manufacturing enterprises, strictly implements motor standard process, and selects high-quality energy-saving materials to ensure the quality of motor products.

About Us

Shijiazhuang ZCL Electric Motor Technology Co., Ltd. is a company mainly engaged in the manufacture, research and development and sales of motor products. The company has many types of motor products, including IEC standard motors. It is a professional IEC motor manufacturer. Related motor products have passed product certification in China, the United States, Canada, Europe, the Middle East and other regions, and the products are exported to all over the world. Companies adhere to the "focus on products, service" business philosophy, and are committed to improving the quality of safe motor products and services for customers around the world.

Frequently Asked Questions (FAQ) about Permanent Magnet Synchronous Motor (PMSM):

1. What is a Permanent Magnet Synchronous Motor (PMSM)?

A PMSM is an electric motor that employs permanent magnets to create a magnetic field, offering higher efficiency and smoother operation compared to traditional motors.

2. How does a PMSM work?

PMSMs use the interaction between the permanent magnet's magnetic field and the rotating magnetic field generated by the stator to produce rotational motion.

3. What are the advantages of PMSMs?

PMSMs offer higher energy efficiency, improved power density, precise speed control, and reduced maintenance requirements, making them ideal for various applications.

4. Where are PMSMs commonly used?

PMSMs find applications in various industries, including electric vehicles, industrial automation, robotics, renewable energy systems, and HVAC systems.

5. What is the difference between a PMSM and an induction motor?

Unlike induction motors that rely on electromagnets, PMSMs use permanent magnets, resulting in higher efficiency and torque density.

6. Can PMSMs be used in variable speed applications?

Yes, PMSMs are well-suited for variable speed applications due to their ability to offer precise speed control and high torque at low speeds.

7. Are PMSMs environmentally friendly?

Yes, PMSMs contribute to energy conservation and reduced carbon emissions, making them more environmentally friendly compared to traditional motor types.

8. How do PMSMs contribute to energy efficiency?

The permanent magnet design reduces losses in the motor, leading to improved energy efficiency and lower operating costs.

9. What maintenance is required for PMSMs?

PMSMs generally require less maintenance due to the absence of brushes or slip rings, resulting in reduced wear and tear.

10. Can PMSMs be used with renewable energy systems?

Yes, PMSMs are commonly integrated into renewable energy systems like wind turbines and solar trackers due to their high efficiency and reliability.

Remember, if you have any specific queries or require further information about PMSMs, feel free to ask!

Permanent Magnet Synchronous Motor

A Permanent Magnet Synchronous Motor (PMSM) is a type of electric motor that uses permanent magnets to create a magnetic field within the motor, rather than relying on electromagnets. This design offers several advantages, including higher efficiency, better power density, and smoother operation.

Permanent Magnet Synchronous Motor

A Permanent Magnet Synchronous Motor (PMSM) is a type of electric motor that uses permanent magnets to create a magnetic field within the motor, rather than relying on electromagnets. This design offers several advantages, including higher efficiency, better power density, and smoother operation.

Large Permanent Magnet Synchronous Motor

The stator structure of the high-voltage and high-efficiency asynchronous start large permanent magnet synchronous motor is similar to that of the ordinary Y series high-voltage asynchronous motor.

Large Permanent Magnet Synchronous Motor

The stator structure of the high-voltage and high-efficiency asynchronous start large permanent magnet synchronous motor is similar to that of the ordinary Y series high-voltage asynchronous motor.

40p 1600KW High Voltage Permanent Magnet Synchronous Motor

The drive mode of 40p-1600KW high-voltage permanent magnet synchronous motor adopts the pinion of permanent magnet motor directly driven ball mill, which can greatly improve work efficiency and running cost.

40p 1600KW High Voltage Permanent Magnet Synchronous Motor

The drive mode of 40p-1600KW high-voltage permanent magnet synchronous motor adopts the pinion of permanent magnet motor directly driven ball mill, which can greatly improve work efficiency and running cost.

Synchronous Motors for Air Separation Applications

TK series three-phase synchronous motor is a high-voltage synchronous motor specially designed for air compressors, mainly used in refrigeration and fertilizer industry equipment.

Synchronous Motors for Air Separation Applications

TK series three-phase synchronous motor is a high-voltage synchronous motor specially designed for air compressors, mainly used in refrigeration and fertilizer industry equipment.

Synchronous Motors for Mining Applications

Large-scale synchronous motor ventilation for mines is open-type natural ventilation or can be made into fully enclosed pipeline ventilation.

Synchronous Motors for Mining Applications

Large-scale synchronous motor ventilation for mines is open-type natural ventilation or can be made into fully enclosed pipeline ventilation.

Synchronous 4 and 6 Poles Motors

The T Series 4 and 6 pole high speed synchronous motors are horizontal.

Synchronous 4 and 6 Poles Motors

The T Series 4 and 6 pole high speed synchronous motors are horizontal.

Synchronous 8 to 40 Poles Motors

The 8 to 40 pole synchronous motor is a horizontal three-phase salient-pole synchronous motor.

Synchronous 8 to 40 Poles Motors

The 8 to 40 pole synchronous motor is a horizontal three-phase salient-pole synchronous motor.

Synchronous Motor Manufacturer

Large high-voltage synchronous motors are ventilated by open natural ventilation or can be made into fully enclosed ducted ventilation.

Synchronous Motor Manufacturer

Large high-voltage synchronous motors are ventilated by open natural ventilation or can be made into fully enclosed ducted ventilation.

Synchronous Motor Supplier

Large high-voltage synchronous motors are ventilated by open natural ventilation or can be made into fully enclosed ducted ventilation.

Synchronous Motor Supplier

Large high-voltage synchronous motors are ventilated by open natural ventilation or can be made into fully enclosed ducted ventilation.

187.5RPM 400KW Synchronous Motor

Our 400KW synchronous motor is a high-power AC motor that operates at a constant speed synchronized with the supply frequency. It converts electrical energy into mechanical energy efficiently and is widely used in heavy-duty industrial applications where precise speed control and high torque are essential.

187.5RPM 400KW Synchronous Motor

Our 400KW synchronous motor is a high-power AC motor that operates at a constant speed synchronized with the supply frequency. It converts electrical energy into mechanical energy efficiently and is widely used in heavy-duty industrial applications where precise speed control and high torque are essential.

IE4 Low Voltage Ultra High Efficiency Permanent Magnet Synchronous Frequency Conversion Motor

The High Efficiency Permanent Magnet Motor is three-phase, 380V, fully enclosed fan air cooling, protection class IP54, class F insulation, installation form IMB3, working system S1.

IE4 Low Voltage Ultra High Efficiency Permanent Magnet Synchronous Frequency Conversion Motor

The High Efficiency Permanent Magnet Motor is three-phase, 380V, fully enclosed fan air cooling, protection class IP54, class F insulation, installation form IMB3, working system S1.

High-voltage High-Efficiency Permanent Magnet Variable Frequency Synchronous Motor

The stator structure of the high-voltage and high-efficiency asynchronous start permanent magnet synchronous motor is similar to that of the ordinary Y series asynchronous motor.

High-voltage High-Efficiency Permanent Magnet Variable Frequency Synchronous Motor

The stator structure of the high-voltage and high-efficiency asynchronous start permanent magnet synchronous motor is similar to that of the ordinary Y series asynchronous motor.

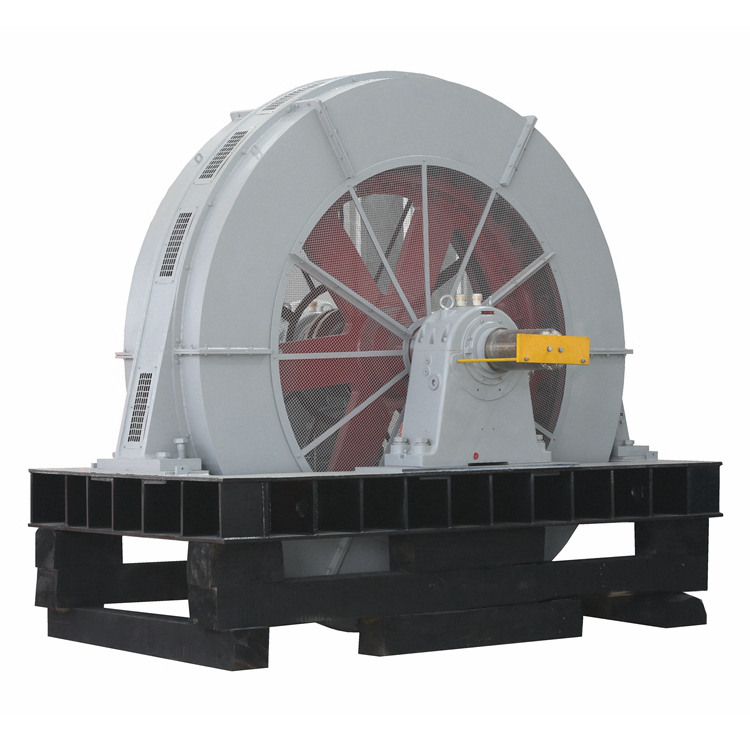

Large Synchronous Excitation Electric Motor

The large synchronous motor is a horizontal three-phase salient-pole synchronous motor. The installation method of the motor is horizontal installation. The outer casing of the motor has a circular structure, the protection grade is IP20, and the cooling mode is open ventilation cooling.

Large Synchronous Excitation Electric Motor

The large synchronous motor is a horizontal three-phase salient-pole synchronous motor. The installation method of the motor is horizontal installation. The outer casing of the motor has a circular structure, the protection grade is IP20, and the cooling mode is open ventilation cooling.

TDMK large synchronous slip ring motor for ball mill

This series of ball mill synchronous motor is mainly suitable for large AC three-phase synchronous motor used in transmission mine mill. The main transmission lattice ball mill, rod mill, coal mill mining equipment.

TDMK large synchronous slip ring motor for ball mill

This series of ball mill synchronous motor is mainly suitable for large AC three-phase synchronous motor used in transmission mine mill. The main transmission lattice ball mill, rod mill, coal mill mining equipment.

Copyright © ZCL Shijiazhuang Electric Motor Technology Co.,Ltd.(中磁力石家庄电机科技有限公司)All Rights Reserved | Sitemap | Powered by