The slip ring induction motor is a wound three-phase asynchronous motor. This series of motors is a derivative of the original JR slip ring motor. It is a new product that optimizes product structure and improves process design, maximizing the use of heavy-duty equipment.

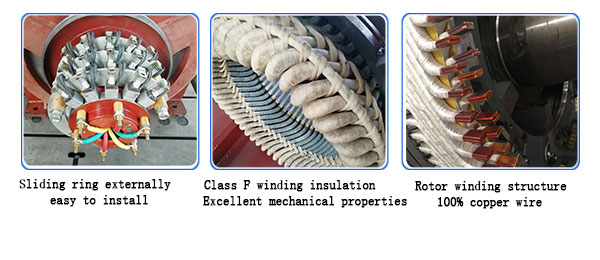

The mechanical strength of the slip ring induction motor winding is high, which improves the insulation level of the motor. The slip ring and carbon brush device of the motor are placed outside the end cover, which can effectively prevent carbon dust from contaminating the coil. At the same time, it is also easy to replace the repair. In the manufacturing process, the power frequency to ground pressure test of the turn-to-turn pulse withstand tester was carried out. The stator and rotor windings were made of F-grade insulating varnish and cured by high temperature drying. The insulation performance of the motor was stable and reliable.

The high voltage slip ring induction motor is a new product motor based on the original JR winding slip ring motor. The motor installation size and power and voltage level are consistent with the original JR motor, ensuring no difference in replacement for the customer. Meet the prescribed standards of relevant technical conditions.

The high-voltage slip ring induction motor adopts the rotor string resistance full-voltage start-up, and has the advantages of small starting current, large starting torque, high efficiency, low noise, small vibration, good ventilation performance, reliable operation, convenient installation and maintenance, and the like.

High-voltage slip ring induction motors are widely used in mining machinery, such as ball mills, crushers, etc. Can also drive a variety of different machines, such as fans, compressors, pumps, cutting machines, transportation machinery and other equipment

ZCL is a professional Slip Ring Induction Motor Manufacturer in China, Contact us online now for a quote.

Definition: A slip ring induction motor is referred to as an asynchronous motor as the speed at which it operates is not equal to the synchronous speed of a rotor. The rotor of this type of motor is wound type. It comprises of a cylindrical laminated steel core and a semi-closed groove at the outer boundary to accommodate a 3-phase insulated winding circuit.

Motor power range: 80KW-850KW

Rated voltage: 3000V/33000V/6000V/6600V/10000V/11000V

Number of poles: 6/8/10/12

Rated frequency: 50Hz/60Hz

Protection level: IP23

Cooling method: IC01

Working system: S1

Insulation class: B

Wiring method: △

Installation method: B3 (horizontal installation)

Ambient temperature: ≥ -15 ° C and ≤ 40 ° C

The deviation of the rated voltage of the YRQ ball mill motor does not exceed 5%, the allowable deviation of the frequency is 1%, and the sum of the absolute values of the deviations does not exceed 5%.

The high-voltage slip ring induction motor adopts the rotor string resistance full-voltage start-up, and has the advantages of small starting current, large starting torque, high efficiency, low noise, small vibration, good ventilation performance, reliable operation, convenient installation and maintenance, and the like.

High Starting torque with low starting current. Maximum starting can be attained in the slip ring motor compared to squirrel cage motor by inserting an external resistance in each phase of the rotor circuit and cutting the resistance during starting

Speeds can be adjusted in the case of slip ring (wound rotor) induction motor by inserting an resistance. Hence slip ring motors are considered as variable speed motors.

Slip ring motors have high over loading capacity, smooth acceleration under heavy loads, and no abnormal heating during starting

The construction of a slip-ring induction motor is complicated because it consists of slip-rings and brushes while the squirrel cage induction motor has simple construction.

The slip ring induction motors have high starting torque with low starting current whereas squirrel cage motors have low starting torque and high starting current.

Slip-ring motor has smooth acceleration under heavy loads as compare to the squirrel cage motor.

There is no abnormal heating during starting of the slip ring motor whereas adequate heat is generated in squirrel cage motor due to high starting current.

The speed control of slip-ring motor is very easy as compared to squirrel cage motor.

For starting the slip ring induction motor rotor resistance starter is required whereas the squirrel cage motor may not require any starter.

Slip ring motors have good running characteristics as compared to squirrel cage motors.

For the slip ring induction motors, the initial and maintenance costs are higher than those of squirrel cage induction motors.

Slip ring induction motors have lower efficiency than the squirrel cage induction motors.

The power factor of slip ring induction motors is low as compared to squirrel cage motors.

The operation of slip ring induction motor is more sensitive to the fluctuations in supply voltage as compared to the squirrel cage motor.

The copper loss is greater in a slip ring induction motor as compared to squirrel cage motor.

Slip ring induction motors are mainly used in applications where high starting torque is required such as cranes, hoists, conveyors, etc. while the squirrel cage induction motors are used in general application like lath machine, drill machine, pumps and fans, etc.

Summary of Differences between Squirrel Cage & Slip Ring Induction Motors

| Parameter of Comparison | Squirrel-Cage Induction Motor | Slip-Ring Induction Motor |

| Rotor Type | Squirrel cage type rotor with permanently short circuited rotor bars. | Wound type rotor with 3-phase windings similar to stator winding. |

| Construction | Simple | Complicated |

| External Rotor Resistance | It is not possible to add external resistance because the rotor bars are permanently shorted with the help of end rings. | External resistance is to be added during starting. |

| Starting Torque | Low | High |

| Brushes | Not used | Used |

| Maintenance | Less maintenance is required. | Frequent maintenance is required. |

| Copper Loss | Low | High |

| Efficiency | High | Low |

| Power Factor | High | Low |

| Speed Control | Not possible | Possible |

| Starting Current | High | Low |

| Cost | Cheap | Expensive |

| Application | In lath machine, fans, pumps, blowers, etc. | In cranes, hoists, elevators, conveyors and loads which require high starting torque, etc. |

Induction motors typically have a lower starting torque than DC series motors Slip-ring induction motors have the huge advantage of high starting torque compared to squirrel-cage motors. Therefore, slip-ring induction motors are typically used where loads require high starting torque or good speed control. They are used in cranes, hoists, compressors, printing presses, large ventilation fans, and loads requiring speed control, such as for driving lifts and pumps.

(1) Greater starting torque than squirrel cage rotor motors is required.

(2) Insufficient feeder capacity to start squirrel cage rotor motors.

(3) Need for a small range of speed regulation.

(4) "Electric shaft" synchronous drive. Such as compressors, sugar mills, textile machines, winches, wire drawing machines, conveyors and other machinery.

The motor products manufactured by our company have obtained the ISO9001 quality management management system certification, passed the CCC/COC, China energy-saving product certification, and passed the certification certificates of CE/UL/IRIS/CAS and other European and American countries. The company strictly improves the quality and efficient motor products and services for users in strict accordance with the requirements of relevant product standards.

Our company's motor manufacturing factory adheres to the concept of green, efficient and energy-saving production service, pays attention to the harmonious development of internal and external environment, builds environmentally friendly motor manufacturing enterprises, strictly implements motor standard process, and selects high-quality energy-saving materials to ensure the quality of motor products.

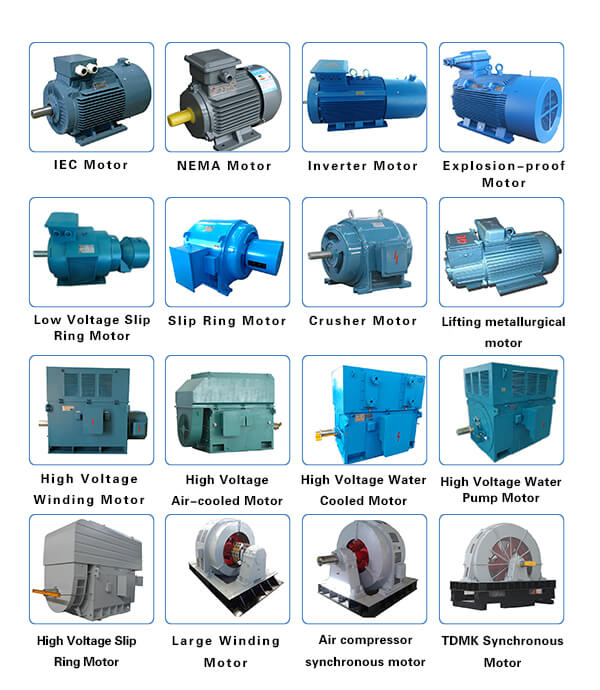

There are many types of motor products manufactured and sold by our company. The main products are high- and low-voltage three-phase asynchronous motors. The motor structure types include squirrel-cage type and winding type. Among them, high-voltage synchronous motors mainly support air compressors and mine ball mill equipment. use. We adhere to the service tenet of "focus on products, service with heart" and provide high-quality motor products to customers.

ZCL is a professional Slip Ring Induction Motor Manufacturer in China. If you are interested in our Slip Ring Induction Motor, please feel free to contact us! Thank you very much!

Shijiazhuang ZCL Electric Motor Technology Co., Ltd.

Add.: Industrial Zone, Zhangjiazhuang Town, Airport Road, gaocheng District, Shijiazhuang, Hebei, China

Tel./Fax: 86-13931192007/ 86-311-89246924

Skype:+86-13931192007

QQ: 568151260

Welcome to visit our factory!

E-mail: zclgroup@zcl-group.com

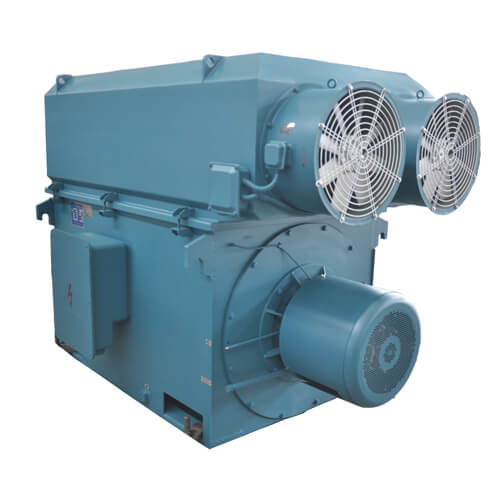

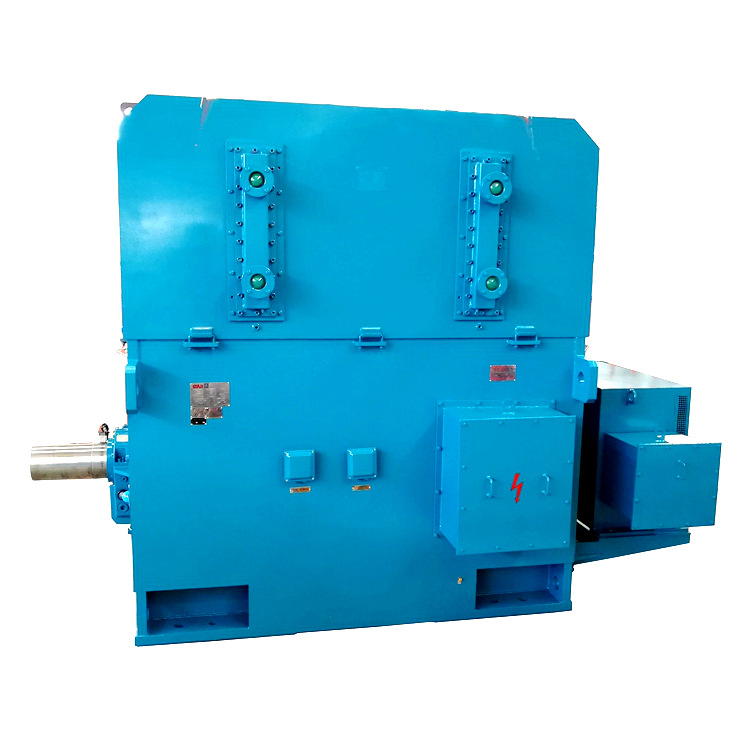

Heavy Duty High Voltage Slip Ring Motor

YR series heavy-duty high-voltage slip ring motor (open type) is a steel plate welding machine base, horizontal structure large-winding three-phase asynchronous motor.

Heavy Duty High Voltage Slip Ring Motor

YR series heavy-duty high-voltage slip ring motor (open type) is a steel plate welding machine base, horizontal structure large-winding three-phase asynchronous motor.

Slip Ring Motor Suppliers

The slip ring motor is a wound three-phase asynchronous motor.

Slip Ring Motor Suppliers

The slip ring motor is a wound three-phase asynchronous motor.

Slip Ring Motor

The slip ring motor is a wound high-voltage asynchronous motor (frame size 355-1000).

Slip Ring Motor

The slip ring motor is a wound high-voltage asynchronous motor (frame size 355-1000).

Slip Ring Motor

YRKK series motors are slip-surrounding three-phase asynchronous motors, which can increase the starting torque at a small starting current.

Slip Ring Motor

YRKK series motors are slip-surrounding three-phase asynchronous motors, which can increase the starting torque at a small starting current.

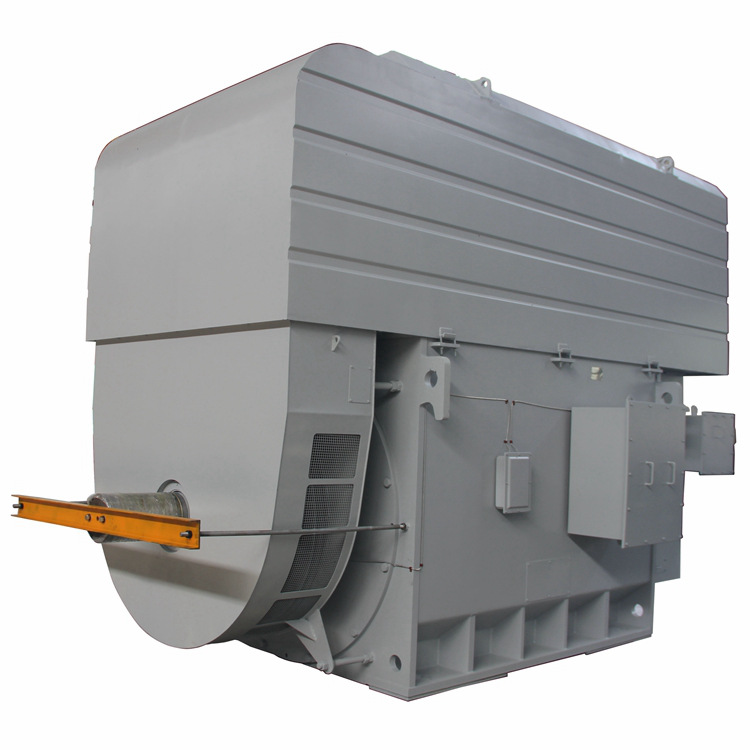

Wound Rotor Motor

The Wound Rotor Motor is a high-pressure slip ring motor developed and manufactured by our company for many years.

Wound Rotor Motor

The Wound Rotor Motor is a high-pressure slip ring motor developed and manufactured by our company for many years.

High-voltage Wound Rotor Slip Ring Motor

The high-voltage wound rotor slip ring motor is a high-voltage three-phase asynchronous motor developed and manufactured by our company for many years.

High-voltage Wound Rotor Slip Ring Motor

The high-voltage wound rotor slip ring motor is a high-voltage three-phase asynchronous motor developed and manufactured by our company for many years.

6kv Slip Ring Motor

6KV slip ring motor is a high-voltage wound rotor three-phase asynchronous motor developed and manufactured by our company for many years.

6kv Slip Ring Motor

6KV slip ring motor is a high-voltage wound rotor three-phase asynchronous motor developed and manufactured by our company for many years.

High Voltage Slip Ring Induction Motor

YRKK series HV slip ring induction motors are used in the motors of heavy-duty starting equipment such as ball mills, rolling mills, sugar mills, crushers, etc.

High Voltage Slip Ring Induction Motor

YRKK series HV slip ring induction motors are used in the motors of heavy-duty starting equipment such as ball mills, rolling mills, sugar mills, crushers, etc.

High Voltage Wound Rotor Induction Motor

YRKS series High Voltage Wound Rotor Induction Motor are used in the motors of heavy-duty starting equipment such as ball mills, rolling mills, sugar mills, crushers, etc.

High Voltage Wound Rotor Induction Motor

YRKS series High Voltage Wound Rotor Induction Motor are used in the motors of heavy-duty starting equipment such as ball mills, rolling mills, sugar mills, crushers, etc.

JR slip ring motor for ball mill

JR ball mill motor adopts rotor string resistance full-voltage start-up, which has the advantages of small starting current, large starting torque, high efficiency, low noise, low vibration, good ventilation performance, reliable operation, convenient installation and maintenance.

JR slip ring motor for ball mill

JR ball mill motor adopts rotor string resistance full-voltage start-up, which has the advantages of small starting current, large starting torque, high efficiency, low noise, low vibration, good ventilation performance, reliable operation, convenient installation and maintenance.

Copyright © ZCL Shijiazhuang Electric Motor Technology Co.,Ltd.(中磁力石家庄电机科技有限公司)All Rights Reserved | Sitemap | Powered by