Brand: ZCL

Product Origin: China

Delivery Time: 20-50 days

Supply Capacity: 1000 units/month

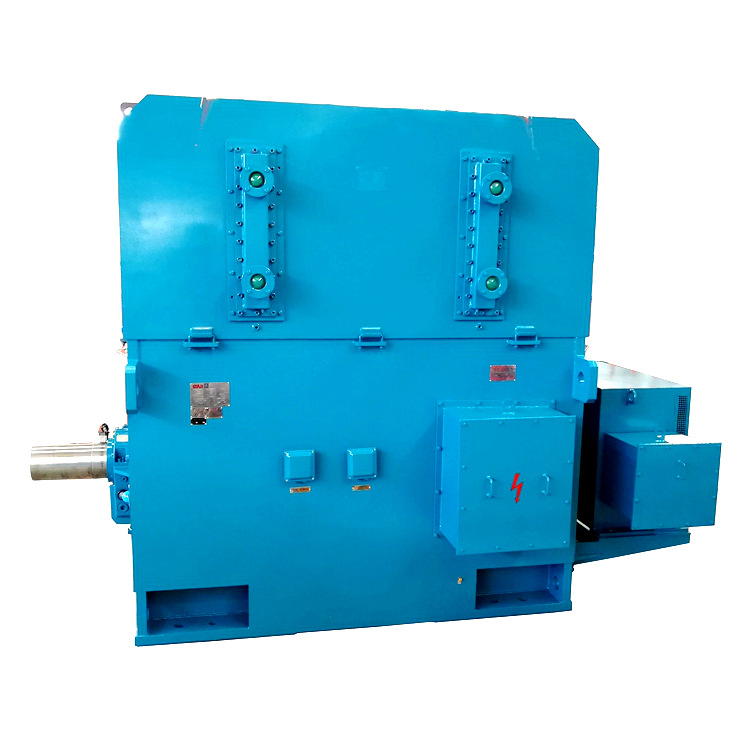

The asynchronous slip ring motor is a high voltage wound three-phase asynchronous motor. This series of motors is a derivative of the original JR slip ring motor. It is a new product that optimizes product structure and improves process design, maximizing the use of heavy-duty equipment.

The asynchronous slip ring motor winding has high mechanical strength, which improves the insulation level of the motor. The slip ring and carbon brush device of the motor are placed outside the end cover, which can effectively prevent carbon dust from contaminating the coil. At the same time, it is also easy to replace the repair. In the manufacturing process, the power frequency to ground pressure test of the turn-to-turn pulse withstand tester was carried out. The stator and rotor windings were made of F-grade insulating varnish and cured by high temperature drying. The insulation performance of the motor was stable and reliable.

JR series high-voltage asynchronous slip ring motor is a new product motor based on the original JR winding slip ring motor. The installation size and power and voltage level of this model are consistent with the original JR motor, ensuring no difference in replacement for customers. The motor complies with the relevant standards of the relevant technical conditions.

JR series high-voltage asynchronous slip ring motor adopts rotor string resistance full-voltage start-up, which has the advantages of small starting current, large starting torque, high efficiency, low noise, low vibration, good ventilation performance, reliable operation and convenient installation and maintenance.

JR series high-voltage asynchronous slip ring motors are widely used in mining machinery, such as ball mills and crushers. It can also drive a variety of different machines, such as fans, compressors, pumps, cutting machines, transport machinery and other equipment.

Product Parameters

Motor power range: 80KW-900KW

Rated voltage: 3000V/33000V/6000V/6600V/10000V/11000V

Number of poles: 6/8/10/12

Rated frequency: 50Hz/60Hz

Protection level: IP23

Cooling method: IC01

Working system: S1

Insulation class: B

Wiring method: △

Installation method: B3 (horizontal installation)

Ambient temperature: ≥ -15 ° C and ≤ 40 ° C

The deviation of the rated voltage of the YRQ ball mill motor does not exceed 5%, the allowable deviation of the frequency is 1%, and the sum of the absolute values of the deviations does not exceed 5%.

Feature of Product

JR high-voltage asynchronous slip ring motor adopts rotor string resistance full-voltage start-up, which has the advantages of small starting current, large starting torque, high efficiency, low noise, low vibration, good ventilation performance, reliable operation, convenient installation and maintenance.

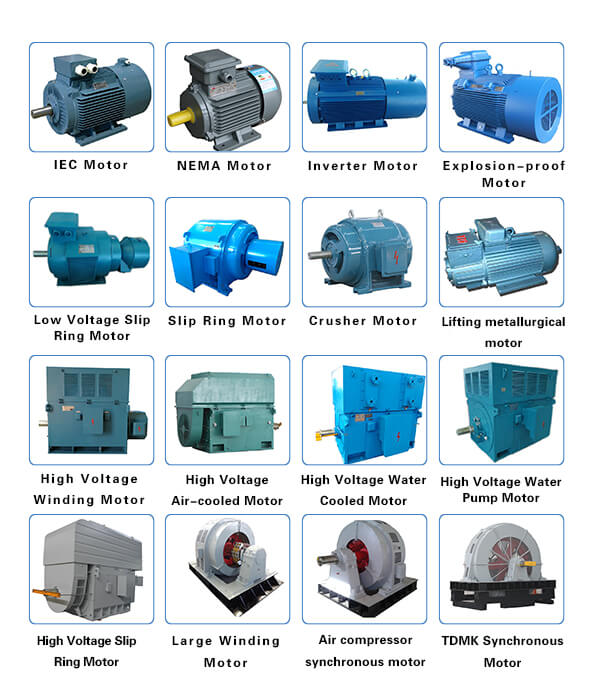

More Product

There are many types of motor products manufactured and sold by our company. The main products are high- and low-voltage three-phase asynchronous motors. The motor structure types include squirrel-cage type and winding type. Among them, high-voltage synchronous motors mainly support air compressors and mine ball mill equipment. use. We adhere to the service tenet of "focus on products, service with heart" and provide high-quality motor products to customers.

Packing and Shipping

1. The outer packaging of the products are all standard export-oriented wooden plywood packaging.

2. The product packaging is protected by moisture, water plastic soft packaging

3. For products with special transportation requirements (such as temperature, fragile, variability, and easy to get wet), the packaging protection measures will be strengthened, and the target mark will be printed on the package.

4. There are obvious signs and symbols on the packing box that must be paid attention to during transportation and storage (such as position, moisture, rain, shockproof, lifting position, etc.).

Factory Glimpse

Our company's motor manufacturing factory adheres to the concept of green, efficient and energy-saving production service, pays attention to the harmonious development of internal and external environment, builds environmentally friendly motor manufacturing enterprises, strictly implements motor standard process, and selects high-quality energy-saving materials to ensure the quality of motor products.

Customer Visit

The company insists on providing high-quality motor products and services to users, and has won high praise from many domestic and foreign customers. The company will receive many foreign merchants to visit our factory every year, and establish a good cooperative relationship through on-site inspection of our factory. Our company always welcomes customers to visit our factory.

FAQ

More details, welcome to call us!

Q: What are the payment terms?

A: 30% T/T in advance, 70% before shipment

Q: What is your delivery time?

A: Different models with different time, 10-90 days after order confirmed.

Q: What is your MOQ?

A: It depends on model.

Q: Where is your loading port?

A: Shanghai or Tianjing Port, China.

Slip Ring Motor

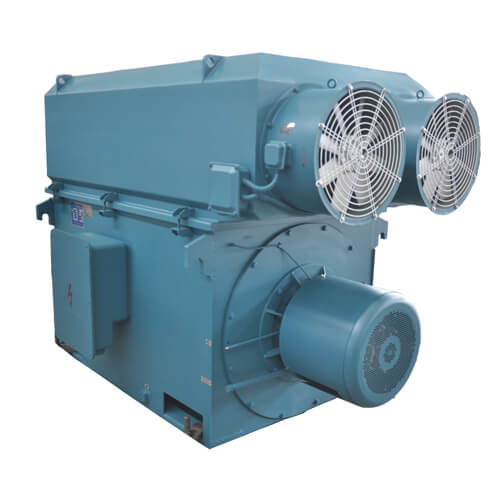

The slip ring motor is a wound high-voltage asynchronous motor (frame size 355-1000).

Slip Ring Motor

The slip ring motor is a wound high-voltage asynchronous motor (frame size 355-1000).

6kv Slip Ring Motor

6KV slip ring motor is a high-voltage wound rotor three-phase asynchronous motor developed and manufactured by our company for many years.

6kv Slip Ring Motor

6KV slip ring motor is a high-voltage wound rotor three-phase asynchronous motor developed and manufactured by our company for many years.

High Voltage Slip Ring Induction Motor

YRKK series HV slip ring induction motors are used in the motors of heavy-duty starting equipment such as ball mills, rolling mills, sugar mills, crushers, etc.

High Voltage Slip Ring Induction Motor

YRKK series HV slip ring induction motors are used in the motors of heavy-duty starting equipment such as ball mills, rolling mills, sugar mills, crushers, etc.

Slip Ring Induction Motor

The mechanical strength of the slip ring induction motor winding is high, which improves the insulation level of the motor. The slip ring and carbon brush device of the motor are placed outside the end cover, which can effectively prevent carbon dust from contaminating the coil. At the same time, it is also easy to replace the repair.

Slip Ring Induction Motor

The mechanical strength of the slip ring induction motor winding is high, which improves the insulation level of the motor. The slip ring and carbon brush device of the motor are placed outside the end cover, which can effectively prevent carbon dust from contaminating the coil. At the same time, it is also easy to replace the repair.

Wound Rotor Motor

The Wound Rotor Motor is a high-pressure slip ring motor developed and manufactured by our company for many years.

Wound Rotor Motor

The Wound Rotor Motor is a high-pressure slip ring motor developed and manufactured by our company for many years.

High Voltage Wound Rotor Induction Motor

YRKS series High Voltage Wound Rotor Induction Motor are used in the motors of heavy-duty starting equipment such as ball mills, rolling mills, sugar mills, crushers, etc.

High Voltage Wound Rotor Induction Motor

YRKS series High Voltage Wound Rotor Induction Motor are used in the motors of heavy-duty starting equipment such as ball mills, rolling mills, sugar mills, crushers, etc.

Heavy Duty High Voltage Slip Ring Motor

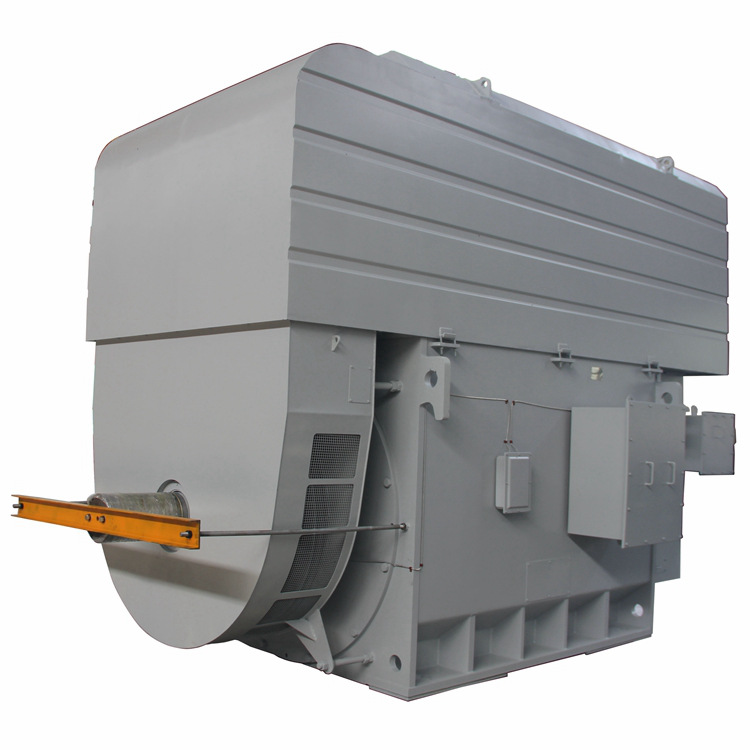

YR series heavy-duty high-voltage slip ring motor (open type) is a steel plate welding machine base, horizontal structure large-winding three-phase asynchronous motor.

Heavy Duty High Voltage Slip Ring Motor

YR series heavy-duty high-voltage slip ring motor (open type) is a steel plate welding machine base, horizontal structure large-winding three-phase asynchronous motor.

JR slip ring motor for ball mill

JR ball mill motor adopts rotor string resistance full-voltage start-up, which has the advantages of small starting current, large starting torque, high efficiency, low noise, low vibration, good ventilation performance, reliable operation, convenient installation and maintenance.

JR slip ring motor for ball mill

JR ball mill motor adopts rotor string resistance full-voltage start-up, which has the advantages of small starting current, large starting torque, high efficiency, low noise, low vibration, good ventilation performance, reliable operation, convenient installation and maintenance.

Slip Ring Motor

YRKK series motors are slip-surrounding three-phase asynchronous motors, which can increase the starting torque at a small starting current.

Slip Ring Motor

YRKK series motors are slip-surrounding three-phase asynchronous motors, which can increase the starting torque at a small starting current.

High Quality Slip Ring Motor

The high-quality slip ring motor adopts box-type structure.

High Quality Slip Ring Motor

The high-quality slip ring motor adopts box-type structure.

High-voltage Wound Rotor Slip Ring Motor

The high-voltage wound rotor slip ring motor is a high-voltage three-phase asynchronous motor developed and manufactured by our company for many years.

High-voltage Wound Rotor Slip Ring Motor

The high-voltage wound rotor slip ring motor is a high-voltage three-phase asynchronous motor developed and manufactured by our company for many years.

Slip Ring Motor Suppliers

The slip ring motor is a wound three-phase asynchronous motor.

Slip Ring Motor Suppliers

The slip ring motor is a wound three-phase asynchronous motor.

Copyright © ZCL Shijiazhuang Electric Motor Technology Co.,Ltd.(中磁力石家庄电机科技有限公司)All Rights Reserved | Sitemap | Powered by