Brand: ZCL

Product Origin: China

Delivery Time: 30-65 days

Supply Capacity: 200 units/month

Y2 series (10KV) high-voltage motor is usually Class F, and the temperature rise limit of the motor for indirect cooling of the air is: when the motor is operated at an altitude not exceeding 1000m and the maximum ambient temperature is not more than 40°C, Class B The insulation temperature rise limit is 80K, and the F-class insulation temperature rise limit is 105K.

Y2 series (10KV) high-voltage motor bearing structure has rolling bearing and sliding bearing structure. The specific structure is determined according to the shape and installation dimension data table. The normal product of sliding bearing structure is forced lubrication, and can also be self-lubricated according to requirements. The motor rolling bearing allows the temperature not to exceed 95 °C; the sliding bearing allows the temperature to not exceed 80 °C when forced lubrication; the sliding bearing allows the temperature to not exceed 95 °C when self-lubricating.

The protection level of Y2 series (10KV) high-voltage motor is different according to the place of use: IP44/IP54/IP55, etc. The cooling mode of this series motor is IC411, and the wiring mode is Y connection. The working system is the S1 continuous working system.

Y2 series (10KV) high-voltage motors are mainly used in fans, pumps, compressors, crushers, chip machines, transportation machinery in explosive gas environments such as petroleum, chemical, coal, power station, metallurgy, transportation, textile, medicine, grain processing, etc. Such as general mechanical equipment or other similar mechanical equipment.

Y2 series (10KV) high-voltage motor, according to the geographical location of the user, the rated voltage of the motor is 3kV, 6kV, 10kV, and the corresponding power supply has a rated frequency of 50Hz. It is also possible to manufacture motors of other voltage levels or other frequencies as required by the user. The technical data in the samples are all data at 50 Hz.

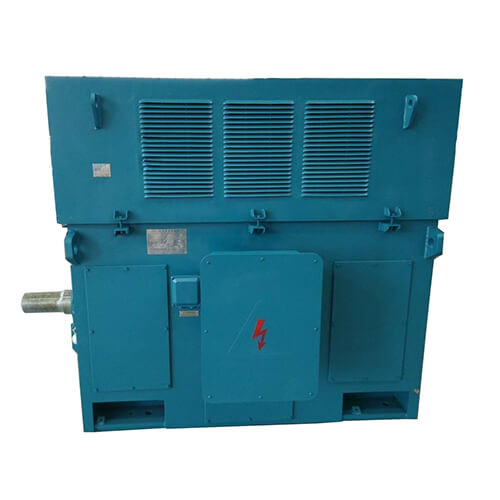

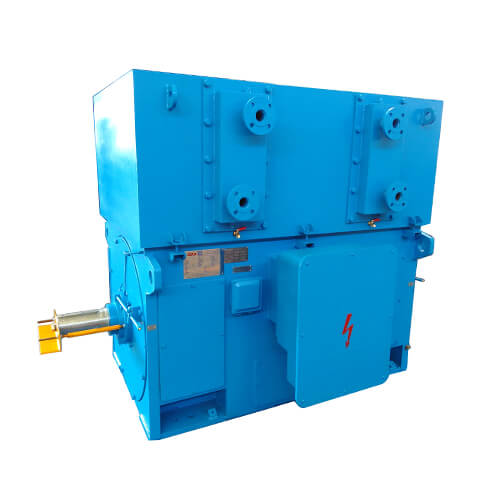

Y2 series (10KV) high-voltage motor is based on the experience of our company for many years of high-voltage motor manufacturing. The large-scale finite element analysis software is used to analyze the structure field, electromagnetic field, temperature field and fluid field level of the motor. At the same time, a new generation of high-efficiency, energy-saving and environmentally-friendly motors designed and manufactured using the principle of dual-cycle cooling ventilation system. It has the advantages of small size, light weight, compact structure, beautiful appearance and smooth lines. This type of motor power rating, electrical performance and installation dimensions are in line with the International Electrotechnical Commission IEC34-1 standard. This series of motors is suitable for dragging compressors, fans, pumps, crushers, metal cutting machine tools, coal mills, transportation machinery, etc. It can also be used as a prime mover in mining industry, machinery industry, petrochemical industry and other industrial and mining enterprises. . Motors used to drive blowers, coal mills, crushers, and rolling mills should provide relevant technical information when ordering to ensure reliable operation of the motor.

The Y2 series (10KV) high-voltage motor has two independent cooling air paths: the inner cooling air path and the outer cooling air path. Most of the heat generated by the loss is transmitted from the stator core to the base and then taken away by the external cooling air. The rest of the heat loss is transferred from the inner cooling circuit to the base and then taken away by the external cooling air.

Y2 series (10KV) high-voltage motor motor base adopts orthogonally distributed full-heating cast iron base. The heat sinks are combined with unequal and non-concentric circles. Four axial air passages are provided in the 45-degree direction. . As the frame is waisted, external cooling air is blown more efficiently from the non-drive end to the drive end along the heat sink for optimum cooling. The junction box is installed at the air passage above the motor side, and does not affect the heat dissipation and the flow of cooling air. The inner surface of the base around the winding end of the stator is provided with a heat absorbing rib. The rib structure of the radiator with a large enough heat dissipation area ensures a strong heat dissipation capability.

Y2 series (10KV) high-voltage motor air vents are installed diagonally on the two horns that can be adjusted at any angle to facilitate motor lifting. The structure of the driving end and the non-driving end of the motor are the same, and there are heat dissipation ribs inside and outside to increase the rigidity of the end cover and the heat dissipation capability. The high-strength cast iron base and end cap ensure high stability of the motor. Under the premise of satisfying the cooling effect, the fan-level fan cover adopts a streamlined design structure, which improves fan efficiency and reduces fan noise.

Product Parameters

Center high range: H450-H560

Power range: 220KW-1400KV

Voltage: 10KV/11KV

Rated frequency: 50HZ/60HZ

Protection level: IP44/IP54/IP55

Cooling method: IC411

Insulation class: Class F

Working system: S1

Wiring method: Y

Field operating conditions:

(1) Normal motor operating location does not exceed 1000M

(2) The maximum ambient air temperature does not exceed 40 ° C

(3) The minimum ambient air temperature is not lower than -20 °C, and the minimum ambient air temperature of the motor with sliding bearing should not be lower than 0 °C.

Feature of Product

Y2 series (10KV) high-voltage motor external fan: 2-pole motor adopts propeller type axial flow fan (one-way rotation); H355-H400 center height 4 pole and above motor adopts basin centrifugal fan, which can rotate in both directions. The H450 and above center high 4-pole motors are all backward-inclined centrifugal fans, which are only suitable for one kind of rotation direction. The other poles are all basin-type centrifugal fans, which can rotate in both directions.

Y2 series (10KV) high-voltage motor stator adopts external press-fit structure, stator winding adopts Class F insulation material, anti-corona (10KV), reliable fixing and binding at the end, and vacuum pressure dipping paint solvent-free process (VPI) The treatment, therefore, the motor has excellent insulation performance, high mechanical strength, long life, strong moisture resistance, corrosion resistance and corona resistance.

The further development of the Y2 series (10KV) high-voltage motors is in the cast-aluminum rotor technology, which has proven successful on millions of low-voltage and high-voltage motors and has developed large-capacity motors. The rotor bars are cast in one piece with the short circuit ring. This technology guarantees the structural robustness and unmatched reliability of cast aluminum rotors. The liquid pure aluminum is poured into the rotor lamination core groove by centrifugal casting aluminum process, cast by one-time casting, and the short-circuit ring and the guide bar are simultaneously cast.

Y2 series (10KV) high-voltage motor bearings are available in both rolling and plain bearings. The motors usually use rolling bearings and use plain bearings when conditions (depending on speed, load and operating conditions) exceed the limits.

Y2 series (10KV) high-voltage motor main power junction box is divided into steel plate tensile junction box, which is characterized by beautiful appearance, light weight, and is suitable for motors with voltage of 3KV/6KV/10KV, with high degree of generalization. The standard design of the motor has two junction boxes, the main junction box and the auxiliary junction box. According to the user's requirements, the main junction box can be installed in four different positions on the ventilation slot to meet the different wiring needs of the site. When there is no special requirement, the main junction box is located at the upper right side of the drive end (looking at the end of the motor shaft) and the bottom line is incoming. The auxiliary junction box is located on the upper right side of the non-drive end (looking at the end of the motor shaft) and the bottom line.

Y2 series (10KV) high-voltage motors provide the following monitoring and protection devices: stator winding temperature measuring element platinum thermal resistance PT100, bearing temperature measuring element platinum thermal resistance PT100, anti-condensation space heater. The temperature measuring components and the heater lead wires are connected to the terminals of the auxiliary junction box.

Packing and Shipping

1. The outer packaging of the products are all standard export-oriented wooden plywood packaging.

2. The product packaging is protected by moisture, water plastic soft packaging

3. For products with special transportation requirements (such as temperature, fragile, variability, and easy to get wet), the packaging protection measures will be strengthened, and the target mark will be printed on the package.

4. There are obvious signs and symbols on the packing box that must be paid attention to during transportation and storage (such as position, moisture, rain, shockproof, lifting position, etc.).

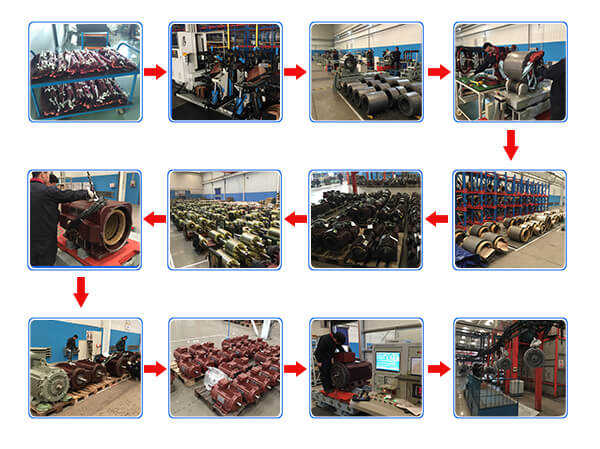

Factory Glimpse

Our company's motor manufacturing factory adheres to the concept of green, efficient and energy-saving production service, pays attention to the harmonious development of internal and external environment, builds environmentally friendly motor manufacturing enterprises, strictly implements motor standard process, and selects high-quality energy-saving materials to ensure the quality of motor products.

Main Process Flow of the Motor

Motor stator: casing processing → punching press → iron core seating → coil making → weaving → dipping paint drying

Electronic rotor: blank shaft processing → iron core press installation → iron core cast aluminum → rotor string shaft → weave → dipping paint drying → dynamic balance

Motor assembly: stator rotor assembly → machine test → motor appearance coloring → packaging storage

About Us

Shijiazhuang ZCL Electric Motor Technology Co., Ltd. is a company mainly engaged in the manufacture, research and development and sales of motor products. The company has many types of motor products, including IEC standard motors. It is a professional IEC motor manufacturer. Related motor products have passed the product certification in China, the United States, Canada, Europe, the Middle East and other regions, and the products are exported to all over the world. Companies adhere to the "focus on products, service" business philosophy, is committed to improving the quality of safe motor products and services for customers around the world.

FAQ

More details, welcome to call us!

Q: What are the payment terms?

A: 30% T/T in advance, 70% before shipment

Q: What is your delivery time?

A: Different models with different time, 10-90 days after order confirmed.

Q: What is your MOQ?

A: It depends on model.

Q: Where is your loading port?

A: Shanghai or Tianjing Port, China.

High Voltage Motor Supplier

Y series (10KV)high-voltage motor adopts box structure, and the motor base is welded by steel plate, which is light in weight and good in rigidity.

High Voltage Motor Supplier

Y series (10KV)high-voltage motor adopts box structure, and the motor base is welded by steel plate, which is light in weight and good in rigidity.

High Voltage Rib Cooled Motors

High Voltage Ribbed Cold Motor is a high-performance cast iron casing motor. The motor is a fully enclosed air-cooled

(TEFC) motor.

High Voltage Rib Cooled Motors

High Voltage Ribbed Cold Motor is a high-performance cast iron casing motor. The motor is a fully enclosed air-cooled

(TEFC) motor.

Hot Selling High Voltage Motor

YKS series (6KV) high-voltage motor is a cage-type rotor asynchronous motor with air-water cooler.

Hot Selling High Voltage Motor

YKS series (6KV) high-voltage motor is a cage-type rotor asynchronous motor with air-water cooler.

High Voltage Squirrel Cage Induction Motor

YKK series squirrel cage high-voltage three-phase asynchronous Induction motor is a cage-type asynchronous motor with closed air-to-air cooler. This series of motors is rated IP44 or IP54 and the cooling method is IC611.

High Voltage Squirrel Cage Induction Motor

YKK series squirrel cage high-voltage three-phase asynchronous Induction motor is a cage-type asynchronous motor with closed air-to-air cooler. This series of motors is rated IP44 or IP54 and the cooling method is IC611.

YTM/YHP/YMPS high-voltage asynchronous motor for coal mill

YTM, YHP, YMPS The motor torque-speed characteristic curve is relatively flat, the starting torque, the maximum torque and the minimum torque are all higher than 3 times the rated torque, and the overload capacity is excellent. It is especially suitable for high starting torque. Mechanical equipment with torque and overload capacity.

YTM/YHP/YMPS high-voltage asynchronous motor for coal mill

YTM, YHP, YMPS The motor torque-speed characteristic curve is relatively flat, the starting torque, the maximum torque and the minimum torque are all higher than 3 times the rated torque, and the overload capacity is excellent. It is especially suitable for high starting torque. Mechanical equipment with torque and overload capacity.

Large Squirrel Cage Motor

YTM, YHP, YMPS series coal mill special three-phase asynchronous high-voltage motor is a closed cage rotor motor.

Large Squirrel Cage Motor

YTM, YHP, YMPS series coal mill special three-phase asynchronous high-voltage motor is a closed cage rotor motor.

High Voltage Motor for Sale

Y series (6KV) high-voltage squirrel cage motor allows direct start at full pressure.

High Voltage Motor for Sale

Y series (6KV) high-voltage squirrel cage motor allows direct start at full pressure.

High Quality High Voltage Motor

YKS series (10KV) high-voltage squirrel cage motor adopts the internationally popular box structure.

High Quality High Voltage Motor

YKS series (10KV) high-voltage squirrel cage motor adopts the internationally popular box structure.

Large Electric Motor

Customized OEM for large electric motors, low voltage and high voltage squirrel cage induction motors, low voltage and high voltage winding rotor slip ring motors, and large synchronous excitation motors.

Large Electric Motor

Customized OEM for large electric motors, low voltage and high voltage squirrel cage induction motors, low voltage and high voltage winding rotor slip ring motors, and large synchronous excitation motors.

GOST A4 Series High Voltage Motor

GOST A4 series high voltage motors are Three-phase asynchronous electric motors with short-circuit rotor. The motor standard is the Russian gost standard.

GOST A4 Series High Voltage Motor

GOST A4 series high voltage motors are Three-phase asynchronous electric motors with short-circuit rotor. The motor standard is the Russian gost standard.

Variable Frequency Three-phase Asynchronous Motor

YPKK series variable frequency three-phase asynchronous motor is the new product series newly designed by our company on the basis of Y, YKK series high-voltage squirrel cage motor.

Variable Frequency Three-phase Asynchronous Motor

YPKK series variable frequency three-phase asynchronous motor is the new product series newly designed by our company on the basis of Y, YKK series high-voltage squirrel cage motor.

High Voltage Induction Motor

Y2 series (6KV) high-voltage induction three-phase asynchronous motor is based on the experience of our company for many years of motor manufacturing.

High Voltage Induction Motor

Y2 series (6KV) high-voltage induction three-phase asynchronous motor is based on the experience of our company for many years of motor manufacturing.

Copyright © ZCL Electric Motor Technology Co., Ltd. All Rights Reserved | Sitemap | Powered by